数字输入/输出 (I/O) 模块

坚固可靠的数字 I/O 模块半导体解决方案

数字输入和输出模块(I/O 模块)是每个 PLC(可编程逻辑控制器)的关键元件。具体来说,它们承担着 PLC 的控制、通信和致动功能。但是数字 I/O 模块面临的挑战越来越多。这些挑战来自日益增长的灵活使用需求,以及在系统可靠性方面同时发生的激烈市场份额争夺战。

不断变化的客户需求也是其中一个因素。解决方案的 IP 保护和访问限制以及其功耗和系统寿命在客户争夺战中发挥着决定性作用。安全方面同样变得越来越重要,特别是在控制驱动器方面。在当今竞争激烈的市场中,长期的经验是基本要素,简单、维护成本低以及数据访问安全等功能也是重点。

开诚布公地探讨合适的开关

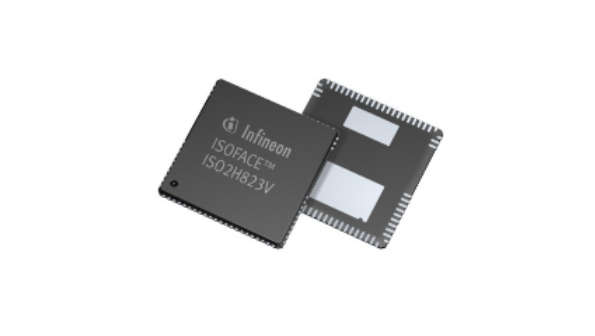

I/O 模块最重要的组件之一是开关。一般来说,可能有两种配置类型:高边和低边。无论何种配置,英飞凌提供的专用解决方案均能协助您的项目。我们的高边 ISOFACE™ 开关以其高水平的集成和稳健性而著称。它们还可以在一个器件内提供电流隔离、保护和诊断反馈。花点时间来探索英飞凌的工业 PROFET™ (保护式 FET) 产品。这些高边开关具有保护和诊断功能,以确保 I/O 模块的安全系统运行。我们的 OptiMOS™ 5 40 伏和 60 伏 系列产品也供您参考,这些产品是英飞凌为 I/O 模块设计的离散解决方案。它们经过热优化,具有最低的 R DS (on)。

HITFET™ 系列是英飞凌为所有低边配置提供的解决方案。内置保护和智能功能使这些组件适用于 PLC 和 I/O 模块。英飞凌是一站式供应商,拥有齐全的高质量解决方案组合,可提供您需要的一切产品。从µC到安全、电源管理、通信,再到保护,应有尽有。让英飞凌的数字 I/O 模块解决方案助您的项目上升到全新水平。

Webinars

Online Courses

Key takeaways:

- Be familiar with the ISOFACE™ family of galvanically isolated high-side switches and input ICs

- Know the benefits that the ISOFACE™ family can provide in the industrial application space

Key takeaways:

- Understand galvanic isolation common to ISOFACE™ products

- Be familiar with the key features of isolated digital output and input products

In this training, we will cover digital I/O in the industrial automation space, including the applications, the relevant international standards, the different digital I/O configurations and which Infineon solutions are available.

In this training, we will take a deep dive into digital input ICs, including how digital input signals are processed, an overview of the applications, the challenges and features, how they can be optimized and the Infineon solutions offered.

In this training, we will take a deep dive into digital output switches, including an overview of the applications, the challenges and features, how they can be optimized and the Infineon solutions offered.

Do you know what industrial automation is?

Join us on this journey through the world of factory automation and find out how semiconductor solutions help factories become smart!

Modern industries typically require many coordinated single steps to accomplish a finished product or any activity flow. Imagine this with no automation in place: any high volume outputs or uninterrupted courses of action at a high level of quality and in a short time would not be possible, would it?