iMOTION™ 集成电机控制(IMC) 具有高度灵活性,助力快速将产品推向市场

iMOTION™ IMC 实现高度灵活性

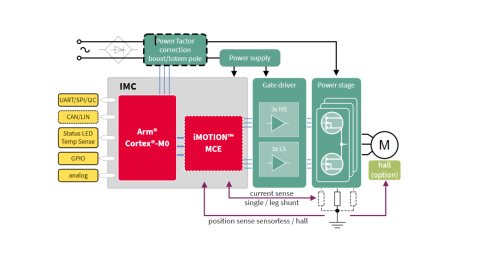

iMOTION™ IMC 产品家族是可用于高效控制变频驱动(PMSM/BLDC)的电机控制 IC。因其即用型的电机控制算法,得以最快速度将产品推向市场,并且可用于控制分立式逆变器或智能功率模块(IPM)。该系列充分应用了英飞凌经实践检验的运动控制引擎技术取得的最新进展。新一代 MCE 对基础算法做出了多项改进,并且实现了一些新特性。

三个 IMC 系列各有不同。IMC099 系列最小巧,它是独立实现的MCE,适用于单电机应用,如风扇和泵机。iMOTION™。IMC100 系列具备类似于小型虚拟机的集成式脚本引擎。IMC300 系列电机控制 IC 除具备 IMC100 系列的特性之外,还加装了一个单片机,从而可以最大限度地提高应用灵活性。

所有 iMOTION™ IMC 器件均可满足 IEC/UL 60730(B类)规定的功能安全要求。

iMOTION™ IMC 产品家族

框图列明了 IMC 产品家族提供的多种不同选项。各个系列均采用了英飞凌经实践检验的运动控制引擎(MCE)技术取得的最新进展。新一代 MCE 对基础算法做出了多项改进,并且实现了一些新特性。

| IMC099 系列 | IMC100 系列 | IMC300 系列 |

| 单核系统 - 单路或三支路分流 霍尔传感器或无传感器 - - TSSOP-38 |

单核系统 脚本引擎 单路或三支路分流 霍尔传感器或无传感器 可选 PFC 控制 - TSSOP-38, QFN-48, QFP-64, QFP-48 |

单核系统 脚本引擎 单路或三支路分流 霍尔传感器或无传感器 可选 PFC 控制 - TSSOP-38, QFN-48, QFP-64, QFP-48 |

iMOTION™ IMC099 系列

iMOTION™ IMC100 电机控制器搭载了运动控制引擎,并采用 TSSOP-38 封装。IMC099T-T038 是一款低成本封装控制器,适用于变速驱动。它可以为永磁同步电机(PMSM)执行无传感器磁场定向控制。

| 特性 | 优势 | 应用 |

| 适用于变频驱动的高度集成式解决方案

新一代运动控制引擎(MCE)

集成保护特性

|

以最快速度将产品推向市场

最低 BOM 成本

为功率级和电机提供完整保护 栅极驱动器和功率级具有极高灵活性 |

|

iMOTION™ IMC100 系列

IMC100 系列专门针对大小家用电器等成本敏感型应用而进行了优化,它们基于单个 MCE 处理内核,同时也集成了小型虚拟机(脚本引擎),能够为用户提供应用灵活性。可以利用标准 iMOTION 工具,生成、测试和下载脚本。作为独立控制器,它们可以搭配英飞凌广阔的 IPM、分立式栅极驱动器和功率级等产品组合中最合适的产品,用于高压和低压应用。

iMOTION™ IMC300 系列

IMC300 采用双核实现,MCE 运行完全独立于单片机,既能兼顾易于使用和可靠电机控制特性,又能最大限度地提高客户应用灵活性。IMC300 系列搭载的 MCE 不仅可以进行无传感器电机控制,也可以在诸如模拟或数字霍尔传感器等传感器的支持下控制电机运行,并且为实现升压或图腾柱 PFC 提供了即用型算法。IMC300 系列器件可用于独立电机控制以及电机控制结合PFC,并可提供 LQFP-48 或 LQFP-64 封装。所有器件均可用于要求具备符合 UL/IEC 60730(B类)规定的功能安全特性的应用。

| 特性 | 优势 | 应用 |

| 完全不需要编程的运动控制引擎,具备与 IMC100 系列完全相同的特性集 升压或图腾柱 PFC 选项 集成保护特性 脚本引擎助力提高应用灵活性 满足 UL/IEC 60730(B类)规定 采用行业标准 ARM® Cortex®-M0 内核的MCU 灵活的外设和通信接口 与 IMC100 系列的引脚高度兼容 |

以最快速度将产品推向市场

完全独立运行的单片机,可实现额外功能和定制通信 最大限度地提高应用灵活性 实现第一级定制的脚本引擎 从 IMC100 轻松灵活扩展到 IMC300 |

|

Find out what iMOTION™ Solution Designer offers you, how projects are created and the work flow in terms of configuration, tuning, dashboards and scripting. The tool guides you through the complete project workflow, achieving the shortest time to market with the lowest R&D efforts.

State of the art sensorless algorithm for permanent magnet motor control is described in this video. Common pitfalls of sensorless control, such as a non-controlled startup are easily avoided with the Motion Control Engine (MCE) inside infineon iMOTION devices. A clean startup, without vibrations and oscillations is demonstrated with a low inertia fan motor.

iMOTION™ ICs integrate hardware and software functionality required for controlling PMSM motors with field-oriented control (FOC) (with and without sensors). iMOTION™ products are based on Infineon’s patented, field-tested Motion Control Engine (MCE), which eliminates software coding from the development process. As a result, all users have to do to implement a variable speed drive is configure the MCE for the respective motor drive system.

Discover how Infineon’s Modular Application Design Kit, or MADK evaluation platform, covers 3-phase motor drive applications with a power level that goes from 20 Watt up to 10 kilowatt.

Infineon offers different solutions for low noise, small, and energy-efficient aircon fan units.

In this training you will get an overview of Infineon's iMOTION™ and CIPOS™ IPMs for both indoor and outdoor unit fans.

The latest software release of Infineon’s iMOTION™ Motion Control Engine (or MCE) supports two kinds of Universal Asynchronous Receiver Transmitter communication options. This training focuses on the Configurable UART communication protocol.

The iMOTION™ Solution Designer bundles all PC-based support functions related to setting up and running iMOTION™ products. This includes the configuration, programming and live tuning using configurable oscilloscopes as well as script editing and debugging. This training will help you get started with iMOTION™ Solution Designer.

Infineon's iMOTION™ family provides active power factor correction integrated digital motor control solutions for different product platforms, including iMOTION™ controllers, iMOTION™ drivers, and iMOTION™ IPMs.

The release of iMOTION™ 2.0 comes at an opportune time. Recent trends in the markets show that inverterization is taking hold at small as well as large companies, being applied across traditional applications, such as refrigerators, and for newer applications like hair dryers and water purifiers. To keep up with the trend, companies are required to convert outdated single speed motors to sophisticated variable speed motor drives. The latest iMOTION™ 2.0 is a close-knit turnkey solution consisting of advanced software, hardware, prototyping & evaluation boards, and support material that makes it easier than ever for customers to go to market cheaper and faster with an efficient, inverterized motor drive solution. Watch this video to get an overview of what is new with iMOTION™ 2.0. Keywords: Inverterization of motor drives

Learn more about the iMOTION™ IPM IMI110 series which is a highly integrated, feature-optimized motor control solution to easily design-in and with a ready-2-use Software, the iMOTION™ solution designer.