How does a factory get smart, digitized, automated and efficient?

Empowering the smart factory

Geopolitical crises, raw material shortages and sustainability regulations are just some of the challenges facing manufacturers. The use of smart factory technologies can help manufacturers meet these challenges and also reap many benefits.

The goal of Industry 4.0 is to create autonomous production in which people, machines, systems and products communicate with each other independently. The result are intelligent value chains and product life cycles in which not only production is controlled, but also the entire value chain, from suppliers and producers to customers can be optimized. This brings a lot of benefits: smart factories can achieve greater productivity and growth, ensure high quality and reduce the risk of human error, provide the right data for analysis and optimization purposes, minimizie downtime and disruptions through predictive maintenance, safeguard the supply chains from disruptions, offer customized products, meet sustainability commitments - to ultimately become more competitive.

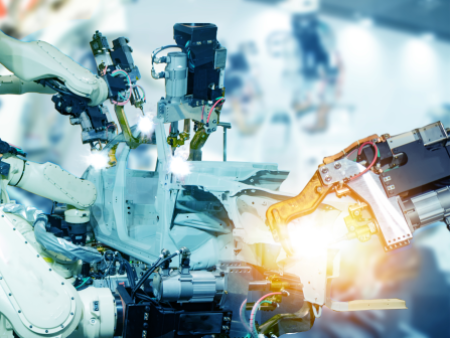

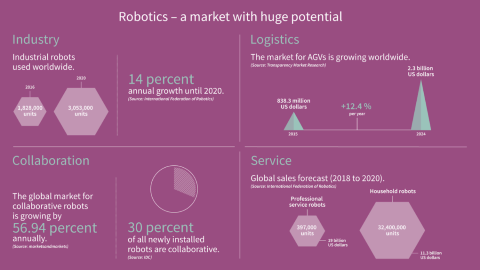

Welcome to the era of robotics

Robotics and Industry 4.0 - Improve productivity

Disruptive technologies have significantly changed our lifestyle in the past few decades. Robots are joining the ranks of innovative and disruptive technologies by revolutionizing traditional habits and processes. Today’s robots can identify and navigate through surroundings, work alongside and even interact with humans. Moreover, they teach themselves the skills required to complete a new task.

According to ABI Research, shipments are expected to grow at a CAGR of 4.5% in 2030 compared to 2020 - for cobots, the expectations are as high as 43%! All this would not be possible without semiconductor solutions. Whether in an industrial robot, a collaborative robot (cobot), a mobile robot for warehouses, last-mile delivery (AGV & AMR) or a domestic robot, intelligent semiconductors are the key enablers for all major robotic functions.

Infineon provides a huge range of components and system solutions for industrial robots, cobots, service robots and more - everything from one single source:

Power electronic components, such as IGBTs and CoolSIC™ MOSFETs, including fitting EiceDRIVER™ gate driver solutions across various power ranges, support a wide range of robotic payloads. CoolMOS™ and CoolSIC™ MOSFETs as well as auxiliary power supply solutions such as CoolSET™ enable efficient power management. PSoC™ microcontrollers are applicable for system control and are also equipped with peripherals to enable connectivity via CAN, USB, or Wi-Fi based on the AIROC™ Wi-Fi & Combos offering. They are also well suited to interface with XENSIV™ sensors to sense the robot’s surroundings. Our range of external memory solutions for code storage and data logging enables the highest reliability, performance, and safety standards. Finally, the OPTIGA™ Trust hardware security solutions provide highly flexible, high-performance, secured access to the cloud.

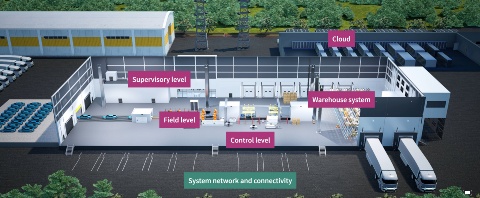

Autonomous production is an important component of the smart factory

Industrial automation for IIoT

The future of industrial automation is brimming with new opportunities to develop superior processes and deliver better products to customers.

During the last years, we've seen everything from a rush on hygiene products and food due to lockdown announcements to a significant shortage of semiconductor chips. These circumstances have led more and more manufacturers to consider ways to optimize their manufacturing processes. This hype in the field of industrial automation is being fueled by other trends mostly triggered by digitalization and sustainability goals - like the demand for power-efficient and industrial grade components with guaranteed long-term availability.

The orientation to the trends poses major challenges for many industrial companies.

- Manufacturing and process control: Shortening the production time to achieve faster throughput.

- Robustness, safety, reliability: Extended life cycle of equipment for less energy and raw material consumption.

- Real-time connectivity: Interoperability of all devices and controls for seamless data flow and continuous data transparency.

- Advanced sensor technologies: Optimization of production flow for early detection of defects.

Infineon provides its customers with the right technologies and innovations to address current and future security, functionality, connectivity and performance demands for industrial automation in smart factories. We offer high-quality industrial grade semiconductors along with a range of proven reference designs. All this makes your automation design as simple, efficient, and reliable as possible.

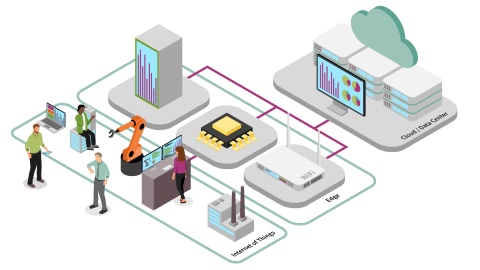

Making data available quickly and securely in the connected factory

Edge computing

Machines and systems generate huge amounts of data in today's factories. To make this data usable in a way that enables automated processes in manufacturing, it must be processed with a very short delay time. This is made possible by edge computing. At the same time, the greatest possible data sovereignty must be ensured so that sensitive customer or production data does not leave the company's own cloud.

Cloud computing has established itself as an integral part of Industry 4.0 in production companies. However, computing power outsourced in the cloud sometimes results in long transfer times. Industrial plants equipped with sensors for realtime requirements, for example, would have to send the current status data to the cloud again and again, which would slow down the required responses accordingly.

This is where edge computing helps

With this technology, data processing takes place close to where it is needed, at the "edge" of the network. In other words, data is not stored and processed in a remote cloud, but where it is generated: in the device itself or from a local computer, server or mini-data center. Collection, analysis and further processing can then take place at the local nodes. The acceleration of data streams data processing can take place in near real time. Ideally, edge and cloud computing go hand in hand for best results.

A strong connection: Edge Artificial Intelligence

Edge AI is an emerging field and growing fast. Edge AI can combine the power of the cloud with the benefits of local operation to improve the performance of AI algorithms over time. The original paradigm of simply moving all of the data generated on the edge to the cloud for analysis and machine learning has run into three fundamental barriers, namely privacy, reliability and latency. Running these algorithms efficiently on edge eliminates these barriers and allows AIoT products to scale much more rapidly. Powerful semiconductor solutions from Infineon create the framework for IIoT at the edge:

- Smart sensors detect and pre-process signals through AI capabilities to recognize potential abnormal operation of equipment

- Edge AI enabled MCUs help to identify at-risk equipment, repair urgency and control adaption

- Smart actuators receive and implement instructions to reduce potential impacts in production

- Security solutions ensure secured communication and protection of critical information

- Connectivity technologies enable dependable communication across devices, factory levels, cloud and secure device management.

IoT solutions prevent failures before they occur – to maximize asset availability

Predictive maintenance

Predictive maintenance offers the potential to optimize maintenance tasks in real time over system lifetime, maximizing the useful life of equipment while still avoiding disruption to operations.

At present, many companies are already using solutions for predictive maintenance, whereby data from machinery is continuously evaluated and compared with past samples. This enables impending malfunctions to be detected before they actually occur. Thanks to the availability of modular IoT sensors and ready-to-use software solutions provided e.g. at ModusToolbox™ for essentials such as machine learning and cloud connectivity, quick implementation without requiring significant up-skilling in data science and AI, a modular condition-monitoring solution is possible and can deliver powerful results that demonstrate the value of IIoT applications.

Leveraging the power of the smart factory

Infineon’s broad range of XENSIV™ sensors can be deployed to monitor everything from single components of production machinery to an entire smart building ecosystem. Typical use cases include HVAC equipment where XENSIV sensors monitor current, vibration, and airflow in motors, compressors, and fans. These sensors can be combined with FreeRTOS-certified XMC™ microcontrollers and OPTIGA™ security solutions so the data collected can be processed and analyzed to enable advanced IoT features such as predictive maintenance.

Using our differentiated memory solutions including Semper™ NOR Flash Memory Family and EXCELONTM F-RAM to reliably and safely store collected data for such analysis, overall system health and safety can be monitored.

Secure

Protect the confidentiality, integrity and authenticity

Infineon’s high-quality industrial security solutions let manufacturers monitor whether or not communication is restricted to authorized people and machines only. They also reliably reveal when a production system has been manipulated, helping avoid unnecessary downtime. They also make secured software updates to devices in the field possible.

The OPTIGA™ security solution family is designed for easy integration into embedded systems to protect the confidentiality, integrity and authenticity of information and devices. These hardware-based security solutions range from basic authentication chips to sophisticated implementations. The OPTIGA™ Trust family includes turnkey products for smaller platforms as well as programmable solutions, while OPTIGA™ TPM (Trusted Platform Module) products are ideal for embedded PC, mobile and computing applications. OPTIGA™ Connect IoT devices enables secured and dependable cellular connectivity, even in harsh environments.

And finally SECORA™ Blockchain is a fast, easy-to-use Java Card™ solution supporting best-in-class security for blockchain system implementation. It makes the application more secure and easier to design for the customer’s blockchain system.

Application examples

Control systems

Powerful control systems form the nerve center of smart factories

Far more data is collected in smart factories than industrial control systems have previously had to process. At the same time, the number of potential applications for industrial control systems has grown alongside Industry 4.0. Yet space costs money—including in factories—which is why the growing number of control systems has been accompanied by demand for smaller system sizes. In turn, this requires flexible electronic components that still need to be sufficiently robust for industrial applications. Microcontrollers are at the heart of every control system, no matter how large or small. Every microcontroller devised for industrial applications must feature real-time performance and advanced connectivity that supports multiple communication protocols. A higher degree of integration minimizes the need for external components and ensures a more reliable solution.

Predictive maintenance

IoT solutions prevent failures before they occur

At present, many companies are already using solutions for predictive maintenance, whereby data from machinery is continuously evaluated and compared with past samples. This enables impending malfunctions to be detected before they actually occur. The BASF facility in Ludwigshafen is a good example, where the company has developed an early-warning system that enables it to plan maintenance on production plants, pumps, motors, and heat exchangers more effectively. This analyzes real-time and historic data, enabling it to predict when maintenance will be required. Yet the functional principle of a smart factory is not limited by location. It can connect machines in different locations with others anywhere in the world, yielding one gigantic virtual factory. At Infineon, for example, facilities in Asia transmit their test results directly to the plant in Dresden, where these are factored into production processes.

Robotics

Smart sensors lend robots sensitivity

Today’s robots are able to detect their surroundings and navigate independently, work side-by-side with humans, and even teach themselves the abilities needed to perform a new task.

Franka Emika’s “Panda” is just one example: The seven-axis robotic gripper arm is distinguished by its ease of handling, high agility, and sensitivity. A combination of numerous sensors, cutting-edge drive technology, and connectivity lends this collaborative robot high sensitivity, adaptability, and cost-effectiveness. Panda has a sense of touch, which enables it to perform complex assembly tasks alongside human colleagues without any safety barriers. The system is operated using apps - just like a smartphone - enabling it to quickly master new tasks. Meanwhile, the design and user interface allow for intuitive programming and flexible application scenarios. As an example, this makes it possible to integrate it into automated processes at a fraction of the cost that would typically be incurred for a robotics application of this kind.

Repel cyberattacks

Protecting devices’ identity and integrity in smart factories

As digitalization continues its unstoppable advance in factories, more and more opportunities for cyberattacks are opening up: According to the “IBM X-Force Threat Intelligence Index 2020”, the number of attacks on industrial systems in 2019 was 2,000 percent higher than in the previous year. Trusted platform modules (TPMs) are just one tool used to repel cyberattacks. These protect the identity and integrity of industrial PCs, servers, control systems, and even edge gateways. The TPM acts as a safe for sensitive data in smart devices and reduces the risk of data loss and production downtimes caused by cyberattacks. Moreover, manufacturers can keep the cost of maintenance low by updating devices’ software remotely and securely.