Digital Input Output (I/O)

Robust and reliable semiconductor solutions for digital I/O modules

From system and operational cost pressure, to multiple system communication standards, to smaller form factors: digital I/O applications currently face a number of challenges. Furthermore, there’s growing demand for flexible use and system reliability is competing for market shares. Evolving customer needs also factor in. A solution’s IP protection and access limitation – as well as its power consumption and system longevity – play decisive roles from the customer perspective. Safety aspects are likewise ever more important, in particular when controlling drives. In this competitive marketplace, long-term experience is key, as are features such as simple, low cost maintenance, and data access security.

Market-leading power switching and security/decryptions solutions from Infineon take these challenges head on. Experts in the field, we maintain close ties with the biggest system manufactures, with whom we collaborate on digital I/O development. Result: robust, reliable semiconductor solutions, such as our ISOFACE™ and PROFET™ families, that optimally fulfill customer needs for input and output control. A one-stop-shop, at Infineon you’ll find all components for your designs, from one trusted source. From µC, to security, to power management, to communication, to protection. Infineon-based digital I/O solutions also meet regional requirements. Discover what you can achieve together with Infineon.

Straight talk about the right switches

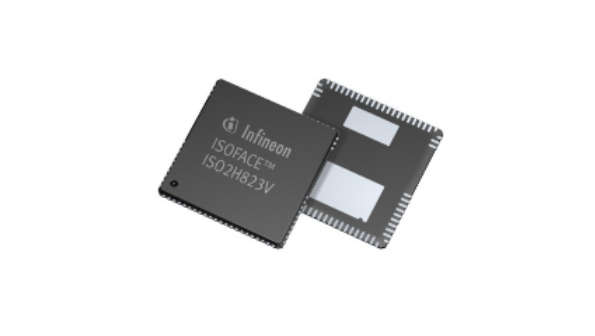

One of the most crucial components of an I/O module is the switch. Generally speaking, two types of configurations are possible: high-side or low-side. Regardless of the configuration, Infineon offers dedicated solutions that boost your project. Our high-side ISOFACE™ switches are known for their high level of integration and robustness. They also offer galvanic isolation, protection and diagnostic feedbacks in one device. Take a moment to explore Infineon's Industrial PROFET™ (PROtected FET) products. These high-side switches include protection and diagnosis functions to ensure safe system operation of I/O modules. Look further to our OptiMOS™ 5 40V and 60V families which are Infineon’s discrete solutions for I/O modules. They are also thermally optimized and feature the lowest R DS (on).

The HITFET™ family is Infineon’s answer to all lowside configurations. Built-in protection and intelligence features makes these components ideal for use in PLCs and I/O modules. A one-stop-shop, at Infineon you’ll find all components for your designs from one trusted source. From µC, to security, to power management, to communication, to protection. Enhance your project with solutions for digital I/O modules from Infineon.

Webinars

Online Courses

Key takeaways:

- Be familiar with the ISOFACE™ family of galvanically isolated high-side switches and input ICs

- Know the benefits that the ISOFACE™ family can provide in the industrial application space

Key takeaways:

- Understand galvanic isolation common to ISOFACE™ products

- Be familiar with the key features of isolated digital output and input products

In this training, we will cover digital I/O in the industrial automation space, including the applications, the relevant international standards, the different digital I/O configurations and which Infineon solutions are available.

In this training, we will take a deep dive into digital input ICs, including how digital input signals are processed, an overview of the applications, the challenges and features, how they can be optimized and the Infineon solutions offered.

In this training, we will take a deep dive into digital output switches, including an overview of the applications, the challenges and features, how they can be optimized and the Infineon solutions offered.

Do you know what industrial automation is?

Join us on this journey through the world of factory automation and find out how semiconductor solutions help factories become smart!

Modern industries typically require many coordinated single steps to accomplish a finished product or any activity flow. Imagine this with no automation in place: any high volume outputs or uninterrupted courses of action at a high level of quality and in a short time would not be possible, would it?