PrimePACK™ IGBT Modules

Power meets requirements

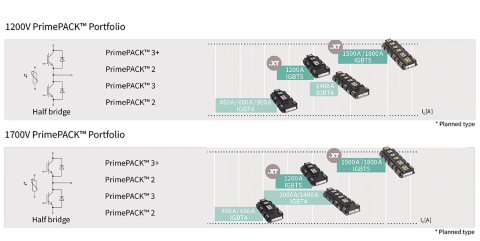

PrimePACK™ IGBT modules cover the full range of 450 – 2400 A at 1200 and 1700 V as well as the latest addition of 2300 V. The modules come in halfbridge and chopper configuration and offer a specially optimized concept for integration in modern converters such as wind, solar, ESS, CAV, Transmission & Distribution or Traction.

PrimePACK™ 2, 3 and 3+ IGBT modules are the preferred choice for powerful, compact and modular converter designs. The compatibility between the footprints allows for an easy upgrade and scalability.

The family of PrimePACK™ modules has constantly evolved and features different IGBT chip generations from IGBT4 over IGBT5 to IGBT7 to fulfill customer requirements.

PrimePACK™ with IGBT4

The standard PrimePACK™ modules with IGBT4 come in halfbridge or chopper configuration. The PrimePACK™ 2 and 3 packages offer high power density and thus enable compact inverter sizes.

This family of IGBT modules is available in 1200 and 1700 V TRENCHSTOP™ technology. It comes with an integrated NTC with high isolation.

PrimePACK™ with IGBT5 and .XT

Wind power applications require a high reliability and robustness, combined with system availability and long lifetime.

PrimePACK™ modules with IGBT5 and .XT meet those requirements: IGBT5 allows higher power density, whereas the .XT interconnection technology extends the lifetime by increased thermal and power cycling capabilities.

The IGBT5 chip generation allows for an increase in output current by around 30%, which made some changes to the PrimePACK™ housing necessary.

Download the whitepaper to read about the new housing investigation and an inverter under real application conditions

.XT interconnection technology addresses all reliability relevant levels within the power module package in order to realize long lifetimes under thermo-mechanical stress. In this whitepaper, the correlation of thermal cycling test data was correlated with the responsible failure mechanisms was explored.

PrimePACK™ with TIM as an option for IGBT4, IGBT5 and IGBT7

Both IGBT4 as well IGBT5 PrimePACK™ modules are available with pre-applied thermal interface material (TIM).

PrimePACK™ IGBT modules with TIM increase system reliability and optimize the thermal management e.g. an 8 K reduction in Tj is observed when using Infineon’s TIM without the pump-out threat and degradation of thermal stability.

In addition handling in mounting and maintenance can be improved. This reduces process time in manufacturing.

Thermal interface material (TIM) is a key component in the majority of power electronic systems. Heat, generated by the semiconductors, has to be transferred to a heat sink and finally to ambient.

In this paper, you will read about the needs and the steps described in developing a thermal interface material, especially dedicated for the use in power electronics.

PrimePACK™ 2300 V with TRENCHSTOP™ IGBT7

Solar power plants with central inverters are essential power sources for the worldwide energy supply of the future. Based on the continuous power increase of these solar plants, the elevated operation voltage of 1500 V has become the new standard.

This paper presents the latest TRENCHSTOP™ IGBT7 and emitter-controlled 7th generation diode of the new 2300 V voltage class. These technologies were developed to meet the requirements of solar central converters with a DC-link voltage of 1500 V. Especially the cosmic radiation failure rate is limiting the usage of devices with nominal voltages up to 1700 V.

This paper introduces a new power semiconductor solution allowing NPC2 designs in megawatt solar central inverters using 1500 VDC operation voltage. The NPC2 solution is based on a PrimePACK™ 3+ IGBT power module rated at 2300 V combined with a PrimePACK™ 3+ 1200 V module in common collector configuration with the latest TRENCHSTOP™ IGBT7 technology from Infineon.

Let the sun shine with Infineon’s new 2300 V PrimePACK™ 3+ module for 1500 V PV central inverters. In this training, you can get to know them.

Today, electrification is revolutionizing transportation. But commercial, construction and agricultural vehicles, pose challenges for power electronics. Machines operate anywhere from the artic to the desert, have a long operating life and minimum down time – and are constantly exposed to shock and vibration. Electrification brings a world of new opportunity to CAV – and Infineon equips your designs with expert solutions destined for the future.

Infineon's high power IGBT7 in PrimePACK™ package provides many benefits when compared to previous generations. Stay tuned to know more!

In this training you will take a look at Infineon’s PrimePACK™ family’s latest addition and find out how it provides superior solutions for wind converter designs.

- the history of wind energy and its future challenges

- a comparison between standard IGBTs and PrimePACK™ .XT IGBTs regarding their composition and production processes

- the solution for wind energy production in locations with low wind speeds

Let the sun shine with Infineon’s new 2300 V PrimePACK™ 3+ module for 1500 V PV central inverters. In this training, you can get to know them.

In this training you will get an overview of the PrimePACK™ portfolio and how it fulfils the requirements of heavy duty CAV applications.