Silicon Carbide CoolSiC™ MOSFETs

Silicon Carbide CoolSiC™ MOSFET solutions are the next essential step towards an energy-smart world.

Silicon Carbide CoolSiC™ MOSFETs Unterkategorien

Based on volume experience and compatibility know-how, Infineon introduces the revolutionary CoolSiC™ MOSFET technology which enables radically new product designs. In comparison to traditional Silicon-based switches like IGBTs and MOSFETs, the Silicon Carbide (SiC) Power MOSFET offers a series of advantages. CoolSiC™ MOSFET products from 400 V to 2000 V target a range of applications such as photovoltaic inverters, battery charging, energy storage, motor drives, UPS, auxiliary power supplies, and SMPS.

Silicon Carbide CoolSiC™ MOSFET technology represents the best performance, reliability, and ease of use for system designers. Silicon Carbide (SiC) power transistors open up new degrees of flexibility for designers to harness never before seen levels of efficiency and reliability. High voltage CoolSiC™ MOSFET technology has also provided impressive improvements in reverse-recovery characteristics.

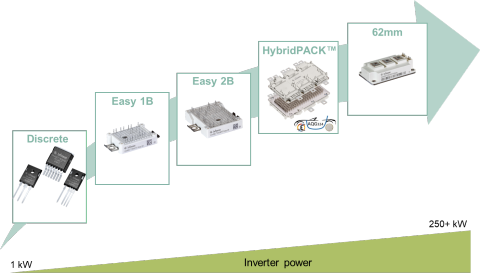

Silicon Carbide CoolSiC™ MOSFETs from Infineon provide high efficiency and optimal reliability. Our range of products is available in discrete housing as well as modules in 650 V, 1200 V, 1700 V and 2000 V voltage classes. Our range of CoolSiC™ MOSFETs includes Silicon Carbide MOSFET discretes and Silicon Carbide MOSFET modules. The SiC MOSFET power modules come in 3-level, fourpack, half-bridge, sixpack, and booster configurations.

CoolSiC™ MOSFET offers a series of advantages. These include the lowest gate charge and device capacitance levels seen in SiC switches, no reverse recovery losses of the anti-parallel diode, temperature-independent low switching losses, and threshold-free on-state characteristics.

Infineon’s unique CoolSiC™ MOSFET adds additional advantages. Superior gate oxide reliability enabled by state-of-the-art trench design, best in class switching and conduction losses, highest transconductance level (gain), a threshold voltage of Vth = 4V and short-circuit robustness. This is the revolution you can rely on.

All this results in a robust Silicon Carbide MOSFET technology, ideal for hard- and resonant-switching topologies like LLC and ZVS, which can be driven like an IGBT or MOSFET with easy-to-use drivers. Delivering the highest-level efficiency at high switching frequencies allowing for system size reduction, power density increases, and high lifetime reliability.

Product line up

CoolSiC™ MOSFET first products in different housings

TO-247-4pin package contains an additional connection to the source (Kelvin connection) that is used as a reference potential for the gate driving voltage, thereby eliminating the effect of voltage drops over the source inductance. The result is even lower switching losses than for TO247-3pin version, especially at higher currents and higher switching frequencies. CoolSiC™ MOSFET Easy modules offer a very good thermal interface, a low stray inductance and robust design as well as PressFIT connections. While low power ranges can be ideally addressed with the Easy family, medium power inverters of 250+ kW can best make use of the 62mm package. The HybridPACK™ Drive CoolSiC™ MOSFETs are AQG-324 qualified and optimized for high power automotive traction inverters of 180+ kW. It is an easy-to-mount SixPack module for direct water cooling with pin-fin baseplate and supports an efficient and high-volume-optimized assembly process.

The world’s first high-performance 1200 V CIPOS™ Maxi SiC IPM in the smallest and most compact package

CoolSiC™ MOSFET based CIPOS™ Maxi IPM IM828 series is the world’s first 1200 V transfer molded silicon carbide IPM which integrated an optimized 6-channel 1200V SOI gate driver and 6 CoolSiC™ MOSFETs.

The smallest and most compact package in 1200 V class, IM828-XCC combines a power rating in excess of 4.8 kW with exceptional power density, reliability and performance.

> Discover more information about CIPOS™ Maxi

SiC MOSFET 650 V and 1200 V Gate Driver ICs

Ultra-fast switching power transistors such as CoolSiC™ MOSFETs can be easier handled by means of isolated gate output sections. Therefore, the galvanically isolated EiceDRIVER™ ICs based on Infineon’s coreless transformer technology are recommended as most suitable.

> More about our EiceDRIVER™ ICs for Silicon Carbide MOSFETs

This video highlights the benefits of CoolSiC™, as seen through the eyes of our customers. Featuring testimonials from alpitronic, Tritium, Lite-On, Siemens Mobility, and Fronius, we see how SiC is driving innovation in energy generation, storage, and consumption.

This video provides valuable insights into the advantages of WBG (SiC & GaN) technology and its potential impact on the future of renewable energy, especially solar and energy storage systems.

CoolSiC™ MOSFET Webinars

This training will introduce you to the gate oxide reliability of CoolSiC™ MOSFETs and how Infineon's design enables the effective screening of defects by opting for a trench MOSFET.

Additionally, you will understand how this decision has allowed Infineon to achieve high reliability that surpasses that of mature silicon technology without negatively impacting key performance parameters.

The switching performance in particular is influenced by the chip's inherent properties, the device's operating conditions and the external circuitry. Optimizing operating conditions and circuitry can significantly improve the device performance in an application.

Circuit designers benefit from SPICE compact models that they can use in computer simulation to understand, troubleshoot and optimize the static and dynamic device behavior of applications through virtual prototyping.

This training explains the characteristics and use cases of simulation models offered by Infineon for CoolSiC™ MOSFETs, what to use them for and how to use them effectively.

This training provides an insight about the system benefits of wide-bandgap devices, which will conquer market share in areas where power density, efficiency and/or battery range are decisive. The training focuses on two applications, mobile chargers and on-board chargers, and will talk about the challenges faced by the solutions today and how SiC and GaN provide next levels of performance.

Watch our webinar to discover more about technological positioning of silicon versus SiC and GaN power devices for both high and low power applications.

CoolSiC™ MOSFET Microlearnings

This training will introduce you to the gate oxide reliability of CoolSiC™ MOSFETs and how Infineon's design enables the effective screening of defects by opting for a trench MOSFET.

Additionally, you will understand how this decision has allowed Infineon to achieve high reliability that surpasses that of mature silicon technology without negatively impacting key performance parameters.

Discover the benefits and challenges associated with connecting SiC power MOSFETs in parallel

By the end of this training, you will be familiar with CoolSiC™ MOSFET 1200 V M1H technology for Easy modules and with Infineon ever-expanding Easy module portfolio in the area of wide band gap material and know about the key features and benefits that are coming along with our latest M1H 1200 V series.

With the growing market of electrical vehicles, the industry has put forward more requirements for the performance of charging piles.

This e-learning will show you that the emergence of CoolSiC™ MOSFETs has improved the charging pile industry to make the EV charger smaller, faster and with higher efficiency.

This training will introduce you to how the CoolSiC™ will help to design the next generation of servo drives.

Driving a CoolSiC™ MOSFET is much easier than you think. This training will show you how it can be driven with a 0 V turn-off gate voltage.

With this training you will learn how to calculate a reference gate resistance value for your Silicon Carbide MOSFET, how to identify suitable gate driving ICs based on peak current and power dissipation requirements and to fine-tune the gate resistance value in laboratory environment based on worst case conditions.

In this video, you will focus on the comparison of the power handling capacity of IGBTs and SiC MOSFETs, Go through the different aspects that need to be considered when dimensioning an IGBT or a MOSFET for a certain application.

- Distinguish the features and benefits of Infineon’s CoolSiC™ solutions in target applications and identify Infineon’s fully scalable CoolSiC™ portfolio to meet this automotive market transition

- Explain the reasons for the increasing introduction of silicon carbide technology in the automotive applications

Infineon offers trusted expertise in all 3 main power semiconductor technologies. Check out how to position them in AC-DC applications!

Click here to find out more.