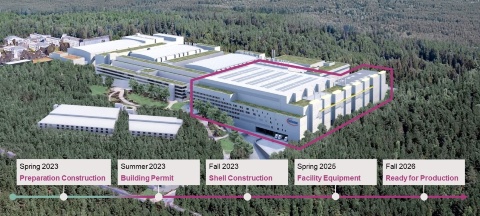

A strong signal for the future

Construction of the Smart Power Fab is on schedule

The handover of the last remaining building permit by Saxony's Minister President Michael Kretschmer in June marks the start of the final construction phase for the new Infineon Dresden plant. Since then, intensive work has been underway on the shell and building construction. The concrete foundation is now almost two meters thick in places.

With an investment volume of five billion euros, the new plant will make a significant contribution to the European Commission's goal of increasing the EU's share of global semiconductor production to 20 percent by 2030. The focus of production is on semiconductors that promote decarbonization and digitalization.

Infineon creates habitats for plants and animals

Infineon has done a lot to create a species-appropriate living environment around the factory premises. These include bat boxes and nesting aids for birds. Additional shelters and warming huts have also been created for lizards and smooth snakes. Infineon is financing these projects as part of the construction work on the Smart Power Fab. The company will also be responsible for their maintenance over the next 20 years.

Other projects include work on the Flößertgraben in the north-west of Klotzsche. Its banks are being restored to their original shape. This will provide improved living conditions for plants and animals and give the neighborhood a new place to linger. Other activities financed by Infineon included the planting of street trees along the Wilschdorfer Mühlweg and the reforestation of a wooded area in the Osterzgebirge.

Setting standards with sustainability

Infineon has already taken important steps towards CO2-neutral production. This includes the existing buildings and production facilities in Dresden as well as the construction of the new Smart Power Fab. Thanks to intelligent solutions, the site of Infineon Dresden has already reduced its consumption of electrical energy by around ten percent and heating energy by over 60 percent in recent years. This is just the beginning: in the coming years, significant savings are expected in air conditioning, compressed air, water treatment and heating systems. In future, the Smart Power Fab will set standards in terms of the consumption of important resources such as energy and water. The investment in Dresden is part of the strategy of Infineon to become CO2-neutral by 2030.

Current construction progress

The construction project has reached an important milestone with the installation of the floor construction for the Smart Power Fab clean room. In technical terms, the prefabricated concrete parts are called waffle tables. The floor has holes with a diameter of 40 centimeters. The air from the clean room will later flow through them into the level below. This allows particles from the air to be drawn to the floor and discharged into the level below. The air returns to the production rooms via cleaning filters installed on the ceiling of the clean room.

The floor of the new clean room formed by the wafer tables – marked orange in the photo – is at the same height as the existing production rooms. This allows the wafers to be transported directly from the existing production rooms to the Smart Power Fab using an automatic transport system. The new clean room is the size of several soccer pitches. Despite this size, the roof construction for the room only requires one row of supports.

A passionate manager

As project manager, Holger Hasse holds a key position in the largest construction project in the history of Infineon, the Smart Power Fab. His role focuses on building and equipping the 20,000 square meter clean room. Added to this is the many times larger area for the technical infrastructure. This construction management is a balancing act: Holger Hasse's mission is to constantly keep an eye on costs, quality and time and to take countermeasures in the event of deviations. Without his constantly growing team, the task would be impossible.

The Smart Power Fab is funded by the European Union, the Federal Republic of Germany and the Free State of Saxony. Sponsors: European Union, Federal Ministry for Economic Affairs and Climate Action on the basis of a resolution of the German Bundestag and the Saxon State Ministry for Economic Affairs, Labour and Transport.