Greenhouse Gas Emissions

Emission reduction strategy

Climate Change is one of the biggest challenges of our times and therefore we understand that efforts from all sectors of society are necessary to deal with this problem.

As a worldwide company, we already integrate climate change aspects and risks in our sustainability strategy and business continuity plans. With this approach, we strive to be prepared and capable of dealing with extreme weather events, ensuring, among others, that there are no significant interruptions in the supply of our products and that the risk associated to people safety is minimized.

At an early stage, Infineon started developing strategies to reduce energy consumption as well as the amount of material used to the minimum technically necessary, thereby limiting CO2 emissions.

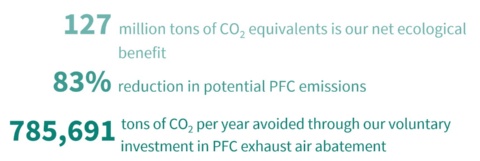

CO2 emissions can also be reduced by limiting perfluorinated compounds (PFCs) emissions. These gases are primarily used in the etching processes needed to structure wafers as well as for the cleaning of production equipment and despite all scientific research, there is no viable alternative to replace all PFCs used at semiconductor industry.

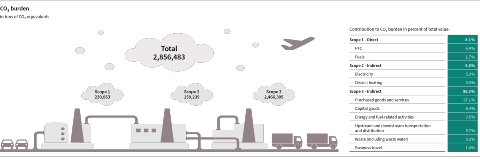

Our Emissions

We commit

The semiconductor industry uses greenhouse gases in wafer-etching processes for structuring wafers as well as for cleaning production equipment.

These greenhouse gases cannot be replaced by another class of substances and account for around 79 percent of scope 1 emissions.

Where possible and appropriate, we counter this trend by continually:

- Optimizing our processes through more efficient production methods and through smart abatement concepts.

- Using alternative gases with higher utilization rates and lower global warming potential also helps minimize the increase in emissions wherever possible.

- Voluntary investing in PFC abatement which enables us to avoid more than three quarters of our potential direct scope 1 emissions, which corresponds to avoiding around 785,691 tons of CO2 equivalents per year.

We perform regular reviews at our sites to identify potential in our own electricity supply. As example:

- Work began in the 2024 fiscal year on the installation of photovoltaic systems at our frontend site in Kulim and our backend site in Melaka (both in Malaysia).

- At our Warstein site (Germany), electricity has been generated from solar energy since the 2023 calendar year.

The potential for our own green electricity production at our sites is limited due to the topology of the buildings and other factors and is in the lower single-digit percentage range with regard to our total electricity consumption.

You can find more about this topic in our Energy Efficiency and Climate Protection page.

We receive excellent results

The carbon footprint is the result of our actions to minimize our emissions. You can see our carbon footprint here.

Have a look on our Sustainability Report page 31-33.