Primary power distribution center (PDC)

Automotive primary power distribution: Providing supply, control, communication, sense, and actuation functions.

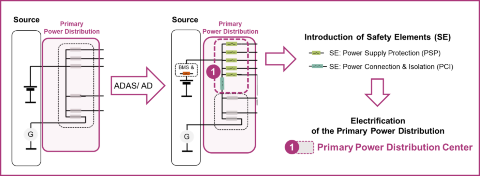

Advanced driver assistance systems (ADAS) and automated drive (AD) functions in modern cars require high availability and fail-operational capabilities. This necessitates the introduction of safety elements in the primary power distribution, leading to partial or full electrification. The primary power distribution center (PDC) replaces the pre-fuse box; providing supply, control, communication, sense, and actuation functions.

From pre-fuse box to primary PDC: Optimizing automotive power distribution

All safety-critical ADAS applications must be designed for high availability. Automated driving (AD) functions are even more challenging to implement as these introduce fail-operational requirements and the so called “dependable electronics” which enable systems that are the foundation for trust.

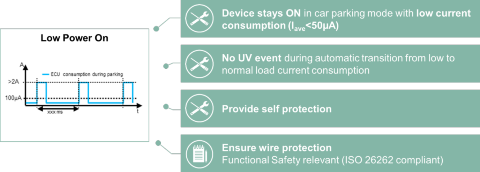

In case of the power distribution system, dependable power is the failure-tolerant supply and distribution of energy throughout the vehicle. The most common physical solution is a redundant supply and distribution of energy to the safety-critical applications. Such systems mandatorily require safety elements to prevent the power distribution system against undervoltage or overvoltage, commonly integrated in the primary PDC.

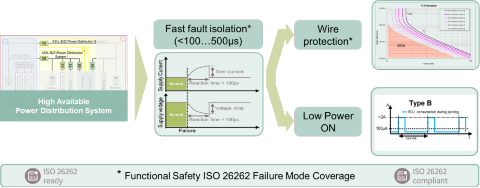

- Diagnostic coverage at 99%

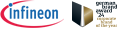

- Fast failure isolation time <100-500 µs

- I2t wire protection

- Low power ON

- Capacitive load switching

Enhanced safety, dependability, and flexibility features

The impact of the ADAS/AD application requirements on the primary power distribution is the introduction of safety elements to guarantee a fast failure isolation in less than 100 µs to 500 µs. As fuses cannot fulfill this requirement, a partial or full electrification of primary power distribution is the consequence. The electrical part of the primary power distribution is no longer called a pre-fuse box, but primary power distribution center (PDC). The primary PDC is a functional block with supply, control, communication, sense, and actuation functions. Infineon provides complete chipset solutions with flexible features for the primary PDC to simplify design-in with scalable product families.

Innovative semiconductor technology for a complete chipset solution

Due to the functional safety requirements, the complexity of the primary PDC is continuously increasing. Infineon offers over two decades of expertise in relay and fuse replacement and functional safety ECU development. Technical documents are available and tools provided to enable easy design-in and reduce time to market.

Examples are:

- Application notes and whitepapers to support relay and fuse replacement

- Arduino shields for easy-to-use device evaluation

- Design-in tools and simulation models for virtual prototyping and system evaluation

- Smart Power Switches Forum to place your questions or provide your supportive feedback.

System understanding to handle design complexities and modifications

The software-defined vehicle development and E/E architecture changes require deep system understanding across the vehicle. We support with functional safety experts, system understanding, and chipset solutions for dependable electronics.

Examples are:

- Globally recognized partner at OEMs and Tier 1 companies for system partitioning and configuration support including functional safety concepts

- Actively contributing to conferences, standardization committees, e.g., VDA, and papers, e.g., Automobile Electronica 2022 edition

- Whitepapers on transition of power distribution and zonal E/E architecture

Premium service for advanced automotive systems

Premium service is a wide field of the Infineon core competence and includes: Operational excellence, zero-defect mentality, disaster and risk management planning, global customer support and distributors, system competence teams, and highest automotive qualification standards.

Examples of standards to support:

- AEC-Q100/101 qualification, leading short-circuit robustness, lowest field return rates (ppb)

- Expanding product families with Grade 0 qualification for harsh environments

- Product families for safety-critical applications to support ASIL-B to ASIL-D with ISO-ready documentation or ISO-compliant development

The optimal way to transport and use electrical energy in the car

Empower your 12 V electrical systems and primary power distribution with Infineon's solutions to meet the escalating power demands for cutting-edge features such as ADAS, autonomous driving (AD), central computing, electrical power steering or steer-by-wire, electro-mechanical braking or brake-by-wire, infotainment, and more.

The adoption of a 48 V based system emerges as the most efficient and compliant approach for the transportation and utilization of electrical energy within the regulatory framework, particularly with regard to contact protection ISO 6469-3. This has spurred significant discussions regarding a comprehensive strategy at the BEV car level, aiming to achieve substantial system-wide cost savings through significant enhancements in efficiency, power losses, and wire harness optimization – encompassing aspects such as cost, weight, complexity, routing, manufacturing, and assembly – all achievable with a 48 V primary power distribution.

The power distribution safety elements have the task to prevent the available Power Distribution System against undervoltage or overvoltage.

There are several reasons why the safety elements have to be implemented by semiconductor:

- One is the diagnostic coverage of semiconductor at 99% compared to fuses, which are on the order of 40%...60%.

- Another is the failure isolation response time. Isolation in less than 100…500 µs is required, which only a semiconductor-based solution can realize. Fuses or relays need much more time and are in the range of several milli seconds.

In case of the power distribution system, dependable power is the failure-tolerant supply and distribution of energy throughout the vehicle. The most common physical solution is a redundant supply and distribution of energy to the safety critical applications. Such systems mandatorily require safety elements to prevent the power distribution system against undervoltage or overvoltage:

For product related support material, please have a look into the product pages

Supply and communication

OPTIREGTM System Basis Chip (SBC)

Microcontroller

TraveoTM II and/ or AURIX™ TriCore™

High-Side Switches, Gate Driver and MOSFET

In this training, you will:

- Indicate what an electrical power distribution center is and describe what solutions Infineon offers for

- Explain why relays and fuses are being replaced with semiconductors and identify the devices that Infineon provides for replacing

Description:

- Explain how the major automotive trends are shaping the evolution of electrical and electronic or E/E architectures in cars

- Identify the trending E/E architecture concepts and their impact on networking technologies and recognize the solutions that Infineon provides to support current and future E/E architectures

In this training, you will:

- Understand what a body control module is and what solutions Infineon offers for standard and high-end body control modules

- Discover why relays and fuses are being replaced with smart switches and identify Infineon's alternative devices