Automotive battery cell monitoring and balancing

Optimize system performance through cell balancing and monitor key battery parameters

The cell monitoring and balancing (CMB) device, also known as the BMS IC or Analog Front End (AFE), measures cell voltages and temperatures for state of charge (SoC), ensuring safe operation within the safe operating area (SOA). It performs low-power diagnostics and housekeeping and communicates with the main controller for cell balancing and pack thermal management triggering disconnection and alerts when needed.

Extending an electric vehicle's driving range and lifetime

Battery packs are constructed by connecting numerous single cells in series, which inevitably result in production variances, for example, different cell characteristics, capacities, or heterogeneous thermal spreads in the pack.

Over time, the small differences between cells in multicell battery stacks are magnified during each charge and discharge cycle. Weaker cells with lower capacity reaching maximum voltage sooner than others force the charging process of the entire pack to stop; in this case, the full capacity of the battery cannot be used.

As a result, using the automotive cell monitoring and balancing (CMB) device to compensate the weaker cells by equalizing the charge across the entire stack is essential in extending an electric vehicle's driving range and lifetime.

Additionally, to achieve extremely low-power dedicated housekeeping functions, such as periodically scheduled cell measurements and state analysis required for functional safety, the CMB can operate independently of the BMS's master controller. Safety features such as signaling over- or under-voltage, thermal stress, and emergency alarms are triggered autonomously.

Enhance your battery balancing design with best-in-class robustness & lowest PPM rates

Infineon's highly integrated products significantly decrease the footprint and help customers reduce costs by minimizing PCB size. Besides, Infineon's zero-defect Mindset is reflected in the lowest PPM rates in the market and significantly reduces vehicle downtime and returns.

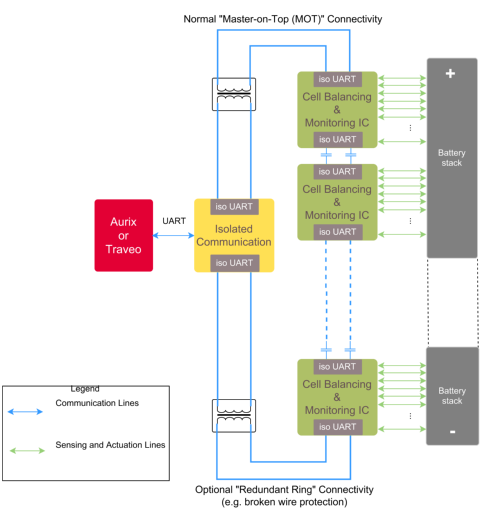

In the wired BMS topology, Infineon offers isolated-UART transceiver solutions with exceptional robustness for both capacitive and inductive types of isolation. The iso-UART offers a robust high-speed communication link across multiple daisy-chained monitoring devices and supports complex cell topologies for a battery. For additional robustness, the daisy-chaining realizes a redundant ring, which keeps communication up between all connected ICs in case of a broken link. CRC-protected data frames complement communication robustness.

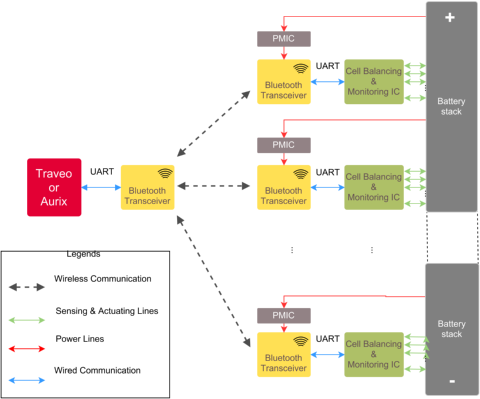

Another method to isolate the CMBs and as such insure the isolation of the battery pack is to use wireless transceivers. The advantage of the wireless topology is that isolation is fully guaranteed at all time.

Infineon offers a set of automotive grade bluetooth devices supporting BLE connected mesh and offering superior network availability and communication bandwidth