Automotive electric pumps and fans 12 V

Electric pumps and fans play a critical role within the thermal management system

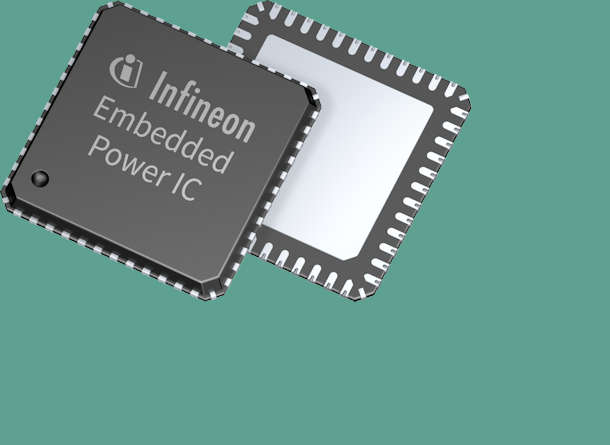

The electrification of small auxiliaries, such as coolant pumps, engine cooling fans, and HVAC blowers, has become a significant driving force in the automotive industry for thermal management. Infineon offers cost-optimized and efficient motor control solutions for mechatronic BLDC motor drives, reducing the PCB size and enabling compact designs.

Electric pumps and fans play vital role in thermal management systems

One of the major driving forces in the automotive industry is the electrification of small auxiliaries, such as coolant pumps, engine cooling fans, and HVAC blowers. They play a very critical role within the thermal management system. Coolant pumps, for instance, are required to cool the battery or inverter, while HVAC blowers ensure that the airflow reaches passengers at the desired temperature and with minimal noise.

The majority of the electric pump and fan market utilizes small, mechatronic BLDC motor drive solutions that require cost- and system-optimized products. Some OEMs in some regions still make use of 1-ph brushed DC solutions for HVAC blowers and engine cooling fans.

- Efficient thermal management

- Integrated and compact solutions

- Various discrete solutions

- Embedded motor control library

- Software development support

Cost- and space-optimized, efficient, and high-performance solutions

Automotive MOSFETs, and sensors are the right choice and state-of-the-art market-integrated solution for mechatronic BLDC motor drive solutions.

Integrated solutions reduce PCB sizes compared to other market alternatives and make them the ideal solution for small, compact designs. Infineon offers a MOTIX™ Motor Control Library for BLDC motor control in addition to our hardware offering which reduces your design efforts significantly.

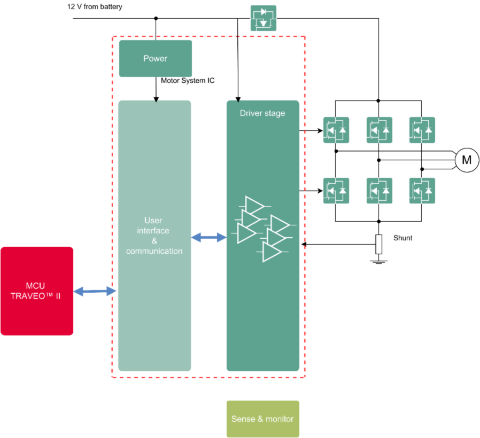

If you require a solution for BLDC motor control applications which offer more computing power, AUTOSAR and embedded security functions (HSM, dual flash bank for OTA), we offer the TRAVEO™ T2G CYT2B6/ CYT2B7 microcontrollers with MOTIX™ TLE9563-3QX or TLE9564QX motor system ICs (SBC) for BLDC motors as a U-chip solution. For brushed DC (unidirectional) motor control, our recommended solution is a MOTIX™ single half-bridge IC with complementary standalone MCUs.

Alternative solution with standalone MCU and MOTIX™ motor system ICs (SBC)

The TRAVEO™ T2G CYT2B7 MCU series offers advanced performance, safety, and security features for automotive body electronics. With a powerful Arm® Cortex®-M4F core, it delivers enhanced performance of up to 1500 DMIPS and integrated network connectivity. Moreover, it provides scalability in memory size and pin count, enabling an MCU solution on a single platform. The family also includes dual-bank flash support for secure updates, embedded HSM for enhanced security, and advanced timer units for precise motor control.

Combined with the MOTIX™ motor system ICs (SBC) for BLDC motors, Infineon offers the ideal alternative solution when more processing power, safety and security features than MOTIX™ 32-bit motor control SoC solutions offer are needed without compromising too much on the overall integration level.

Further discrete solutions with half-bridge ICs

The fuel pump ECU is generally placed outside the fuel tank, while the pump itself is located within. This results in long wires between the ECU and motor, which calls for fast switching speeds to minimize power dissipation. Furthermore, ECU cooling presents its own design challenges: Fuel pump runs continuously, and the ECU is often positioned below the rear seat, where it has limited cooling capabilities.

Our integrated high-current MOTIX™ half-bridge ICs help optimize the power spread and cooling in fuel pump applications. The “worst-case” switching times are specified in the datasheet, allowing you to minimize the switching spread in relation to a discrete MOSFET in particular. The integrated MOTIX™ single half-bridge requires only one single cooling area, which serves both high-side and low-side current switching. Furthermore, this device comes with over-temperature shutdown and latch behavior to protect the MOSFETs thermally. Thanks to the thermal feedback, MOTIX™ half-bridge IC also enhances switching speeds for lower switching losses.

The TRAVEO™ II Entry MCU family is designed for automotive body electronics applications and offers cutting-edge performance, safety, and security features. With processing power and network connectivity built into a single Arm® Cortex®- M4F, this family of microcontrollers has enhanced performance up to 1500 DMIPS. This family also provides the scalability across memory size and pin count and the IP compatibility enable customers to design and develop their system with a single-platform MCU solution. TRAVEO™ II MCUs come with optimized software platform that is available with AUTOSAR MCAL (Microcontroller Abstraction Layer) and HSM Performance Library.

The TRAVEO™ II Entry MCU family offers cutting-edge features like dual-bank flash support for SOTA, embedded HSM and advanced timer units for motor control.

TRAVEO™ II and our MOTIX™ motor system ICs (SBC) for BLDC motors are the ideal solution when require more processing power, safety and security features as with MOTIX™ 32-bit motor control SoC while not compromising too much on the overall integration level.

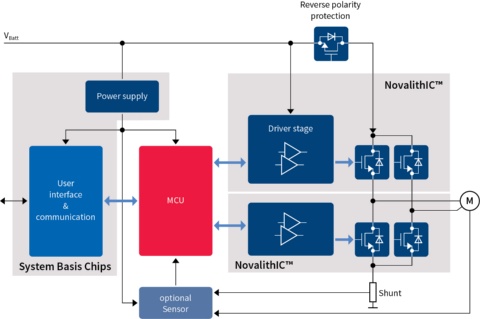

Our TLE956x is the first solution in the market with integrated bridge drivers, power supply and CAN FD / LIN communication interface significantly reducing the required board space and amount of component counts. The products use a patented concept of adaptive MOSFET gate drive. This multi-stage slew rate control enables EMC tuning via SPI, including adjusting slew rate with independence from dead-time and turn on/off delays. Self-adaption of external MOSFET switching allows the balancing of power dissipation vs. EMC performance. This combined with overtemperature protection features such as prewarning and individual thermal shutdown, diagnostic and supervision functions (e.g. fail-safe output, watchdog, fail-safe operating mode and short-circuit protection) embedded within the TLE956x to optimize the power dissipation and thus temperature for use in fuel pump applications.

The fuel pump ECU is generally placed outside the fuel tank, while the pump itself is located within. This results in long wires between the ECU and motor, which calls for fast switching speeds to minimize power dissipation. Furthermore, ECU cooling presents its own design challenges: Fuel pump runs continuously and the ECU is often positioned below the rear seat, where it has limited cooling capabilities.

Our integrated high-current MOTIX™ single half-bridge ICs help optimize the power spread and cooling in fuel pump applications. The “worst-case” switching times are specified in the datasheet, allowing you to minimize the switching spread in relation to a discrete MOSFET in particular. The integrated single half-bridge requires only one single cooling area, which serves both high-side and low-side current switching. Furthermore, it comes with overtemperature shutdown and latch behavior to protect the MOSFETs thermally. Thanks to the thermal feedback, ;the single half-bridge also enhances switching speeds for lower switching losses.

If you want the flexibility discrete solutions offer, you will find the exact components you are looking for in our one-stop-shop of microcontrollers, sensors, SBCs, and MOSFET drivers.

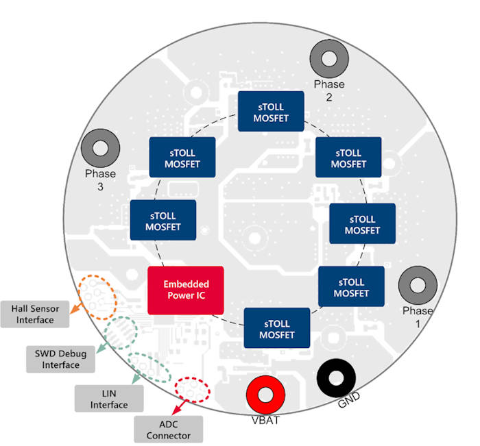

The reference design targets engine cooling fan applications and it is capable to drive 12 V BLDC motors up to 1 kW. It uses the MOTIX™ TLE9879QXW40 32-bit motor control SoC (former embedded Power IC) and the IAUA250N04S6N007 (OptiMOS™-6 40 V MOSFET) as main devices. The reference design offers minimal BOM and reduced PCB size. Furthermore, it is optimized in terms of EMC and thermal performance. It includes layout and schematic files, along with comprehensive support documents including EMC measurements, thermal analysis and a detailed board description.

For more detailed information, please visit our reference design webpage.

The reference design targets auxiliary water pump application and it is capable to drive 12 V BLDC motors up to 140W. It features:

- TLE9879QXW40 (MOTIX™ 32-bit motor control SoC (former embedded Power IC))

- IAUC60N04S6N031H (OptiMOS™-6 40 V MOSFET)

- IPZ40N04S5-3R1 (OptiMOS™-5 40 V MOSFET)

The reference design offers minimal BOM and reduced PCB size. Furthermore, it is optimized in terms of EMC and thermal performance. It includes comprehensive support material including layout and schematic files (Altium), EMC tests, thermal analysis and detailed documentation.

Accelerate your development process and go to market faster with our auxiliary water pump reference design.

For more detailed information, please visit our water pump reference design webpage.

- Are you looking for smart and reliable solutions to drive brushed DC motors in automotive applications?

- Then you will certainly like the integrated and fully protected MOTIX™ single half-bridge integrated circuits.

- Infineon has been expanding the package portfolio for it’s high-performing OptiMOS™ MOSFETs.

- Do you know SSO10T, the latest addition to Infineon’s package family for OptiMOS™ MOSFETs?

Learn how to control MOSFETs in PWM with the evalkits DC/BLDC for MOTIX™ motor system IC . Know how to control the switching times of the external MOSFETs

In this training you will:

- Know more about Infineon’s wide MOSFET selection for 48 V mild-hybrid electric vehicle, or MHEV, applications

- Understand why and how Infineon is strengthening its position in the 40 V MOSFET market, and be familiar with Infineon’s newest 60 V MOSFETs

The microlearning has an application focus on auxiliary pumps and fans. It will give an overview of the application requirements of pumps and fan applications. In detail the key challenges of engine cooling fan, fuel pump, and oil pumps are shown and how those can be solved with Infineon’s highly-integrated system-on-chip solution.

In this training you will:

- Understand the challenges that automotive auxiliary water pump applications face

- Find out about the different topologies used for thermal management for different drivetrains and learn which solutions Infineon provides for automotive water pump applications

In this training you will:

- Know the Power PROFET™ portfolio and understand how Power PROFET™ handles demagnetization

- Identify how to build a robust implementation with Power PROFET™

OptiMOS™ 7 40 volts is Infineon’s new automotive MOSFET technology.

It presents a 25 percent Ron improvement when compared to the previous OptiMOS™ 6.