Medical Ventilator - Inside and outside intensive care units (ICU)

Medical ventilator ICs and system design

Automating a medical ventilator* so that no continual operator intervention is needed for safe, desired operation requires three basic components:

- A power source of input energy to drive the device

- A motor and motor control system to convert input energy into output energy in the form of pressure and flow to regulate the timing and size of breaths

- A control system/controller to monitor the output performance of the medical ventilator device and the condition of the patient to see if the breath was taken

A ventilator is designed to mechanically move air in and out of the lungs to intermittently or continuously assist or control pulmonary ventilation. It can also be used to control human body oxygen levels, for example during surgery where blood loss can result in hypoxia or lack of sufficient oxygen in the patient´s body; it is best to have less human interaction.

Sensors & Microcontroller: The most common indicators of the ventilation are the absolute volume and changes of volume of the gas space in the lungs achieved during a few breathing activities. It requires a set of sensors for pressure, volume, and flow. The sensor information modulates the operations of the microcontroller. Based on the sensor information the MCU controls the motor system of the ventilator pumps.

Alarm system: An important part of the ventilator device is the alarm that informs on patient parameters such as exhaled volume or airway pressure. The ventilation system must be able to detect the breathing activities of the patient. The MCU measures changes in aspiratory flow and pressure by using sensors. If no inspiration is detected within a certain period of time, the monitor sounds an alarm. The conditions programmed depend on each system. Audio amplifiers are used to inform in different alarm cases depending on the situations. PWM cycles can be programmed to sound alarms.

Valve control: The pneumatic system has two air supplies that can be oxygen and air, and can come from a pressurized tank or compressor. Both sources are regulated by two input valves to control mixture composition, which comes from an air tank where the mixture is kept at certain pressure limits. If the mixture composition is correct and is in the right pressure range, the system sends this air to the patient to control breathing. The lungs' elasticity releases the overpressure, this is called passive exhalation, and the exhaled air is released usually through a one-way valve within the patient circuit.

Highly advanced ventilation units are used in acute care respiratory support for adult, pediatric and infant use. The units deliver high-performance ventilation capabilities, comprehensive monitoring, and effective treatment functions.

A wide range of treatment options enables you to manage the needs of virtually any acutely ill patient. These options include for example Low flow PV Loop maneuver, adjustable pressure setting via remote interfaces or buttons and software supported weaning off the treatment.

Smart and connected systems help to manage patient-interface leakage. Smart medical ventilator units recognize and compensate for leakage by adjusting both inspiratory trigger and termination points and maintain therefore optimal synchrony. During transport (outside the ICU) breath support and patient monitoring need to be guaranteed without compromise, too. In this case, batteries supply the needed power for the unit.

In the event of sudden grid voltage loss, UPS systems backup the power supply to ensure a continuous flow and monitoring of the patient. Also, UPS backup the communication networks so that patient data is accessible at any time when needed.

In the blower unit, a brushless dc motor (BLDC) is the basis for the drive of the unit. Those units need to be designed for extreme operating conditions (even high temperatures due to sterilization processes at 134°C), with the highest reliability, precise function, and long service life. Typical features also include very smooth-running operation, low audible noise, high performance and dynamics in a compact size. A small size of the powerhouse is crucial for mobile ventilator designs. The motor control demands that the blower accelerates precisely in milliseconds and slows down again just as quick to adopt to the patient's breath activity and lung performance.

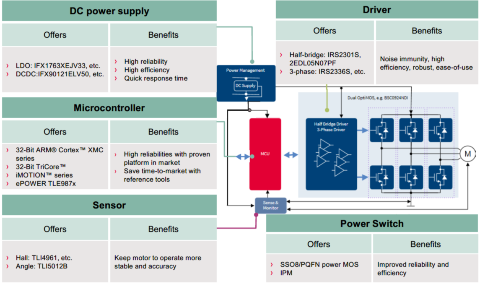

Infineon’s BLDC product offer provides power switches, microcontrollers, dedicated motor control ICs, gate drivers and sensors. Learn more about brushless DC motor control solutions.

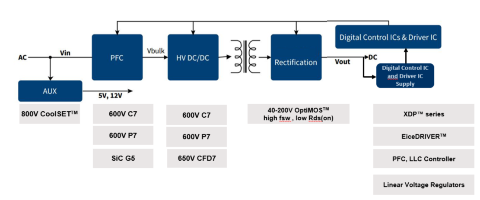

In our broad portfolio of German-quality semiconductor solutions, find the best products, demo boards and reference designs for switch-mode power supplies. All this and more from the only supplier to offer a complete range of semiconductor products for your applications. Also, our team of experts has a deep understanding of your power supply systems and needs.

Power supply, charger and adapter applications with 800 V CoolMOS™ P7 as well as the overall controller design can be realized with Infineon Power ICs. A quasi-resonant flyback topology for improved switching losses which allows higher power density designs and lower radiated and conducted emissions are shown in the 45W eval board. This board demonstrates a 45 W universal input isolated flyback schematic with a 19 V output based on the ICE2QS03G controller and the P7 MOSFET. Find all the information on the board, on schematics and test results.

Learn more about Infineon's AC/DC SMPS.

Counterfeit products can seriously compromise the end-usage of products and may harm devices made by system manufacturers and Original Equipment Manufacturers (OEM). Therefore, it is becoming more and more important for manufacturers to safeguard their products and brands.

OPTIGA™ Trust B is a robust cryptographic solution for embedded systems requiring easy-to-integrate, reliable authentication features. This security solution is designed to help system and device manufacturers safeguard the authenticity, integrity, and safety of their original products. As a turnkey solution, it provides enhanced protection against aftermarket counterfeit replacements, thus helping to maintain OEM authenticity and safeguard the user experience.

Enhanced security for connected / IoT devices with OPTIGA™ TRUST X SLS 32AIA. OPTIGA™ Trust X reduces integration effort and is easy to use – making it ideal for customers who lack security expertise but nonetheless need fast time-to-market. This premium security solution offers high performance and low power consumption. It supports non-rich operating systems and comes in compact packages. It enables new features and business models that help you to differentiate your offering and stay ahead of the competition.

XMC™ in combination with OPTIGA™ Trust can reduce R&D cost for implementation of authentication feature.

*Infineon Technologies points out that the Infineon products are not specifically designed and tested for use in medical applications and that they are qualified either according to an industrial or automotive standard and specified as outlined in the applicable datasheet. It is your responsibility to carefully assess whether the Infineon products fulfill the requirements of your application. Please inform us about such requirements, if any.