Chargers from 50 kW to 350 kW

Efficient design systems for hyper-fast DC charging systems

The outlook for e-mobility is bright. According to the International Energy Agency (IEA)* about 140 percent more electric vehicles (EVs) were sold in the first quarter of 2021 compared to the first quarter of the previous year. Yet, to keep this momentum going, it is critical to make owning an EV as convenient as owning a traditional car, which is where high-power DC charging plays a role.

Encouraging drivers to make EVs their primary means of transportation relies heavily on finding ways to extend their range. While carmakers work on more efficient batteries, equally important is building up a powerful, convenient and accessible charging infrastructure. This need for more range and reliable infrastructure translates to greater demand for more power as fast as possible.

High-power DC charging systems up to 350 kW, allow drivers to add 200 km to their battery in about seven minutes – just enough time to have a cup of coffee on the way to their final destination. The technology that makes these chargers fast, efficient and accessible will help eliminate “range anxiety” among drivers and further encourage EV adoption around the world.

*Source: International Energy Agency (IEA) https://www.iea.org/reports/global-ev-outlook-2021?mode=overview

Selecting the right components

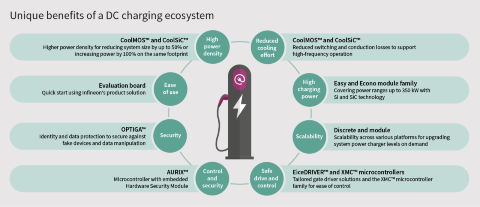

Infineon has the broadest portfolio for EV charging on the market. With our combined system solutions and competence, it is possible to select the best products and technology for every aspect of EV charger design so that customers receive the best price for performance.

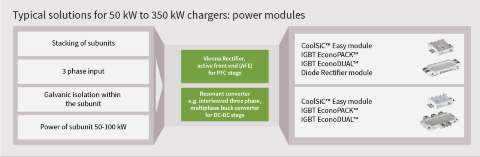

When choosing the ideal power semiconductor, it is important to know the charger’s power level. Ultimately, the selection of suitable devices depends on this factor. Chargers in a power range above 50 kW are commonly built using Infineon’s IGBTs, CoolSiC™ MOSFETs, and diode power modules, such as the CoolSiC™ Easy Module, IGBT EconoPACK™ and the IGBT EconoDUAL™ family. With subunits from 50 kW to 100 kW, chargers with power ranges higher than 100 kW are built by stacking the subunits.

Our high-quality portfolio of power switches works seamlessly with our broad range of drivers. All switches need a driver and all drivers need to be controlled. That is why we also offer the best-fit EiceDRIVER™, as well as XMC™ and AURIX™ microcontrollers for your fast EV charging designs. Infineon’s AIROC™ Wi-Fi & combos portfolio integrates Wi-Fi and Bluetooth® in a single-chip solution. For converter management, our high-precision coreless current sensors offer the ideal solution for converter control and diagnosis. And finally, our line of OPTIGA™ products ensure data protection and security for the charging station.

Technology trends

The aim of high-power chargers is decreasing charging time to make electric vehicles on par with combustion engine cars. There are two possible charging infrastructure architectures: either isolate the primary AC side or the secondary DC side.

Isolating the primary AC side

In a charging park scenario, six to eight high-power charging stations can be made available with an overall power setup of 2 MW to 3 MW, as proven in practice. Power is sourced from a highly-efficient, medium-voltage transformer, typically 22 kV to 500 kV, to isolate the AC side of the system. The AC to DC stage follows, which may or may not involve an active rectifier. Multi-pulse passive rectification is one option to have the current harmonics under the existing standards. Isolating the primary side gives the designer the freedom to use non-isolated DC-DC converter topologies for the DC-DC conversion stage. Usually, a multiphase buck converter is suitable for this architecture with a DC conversion block.

Isolating the secondary DC side

The second infrastructure architecture reaches 350 kW by stacking 50 kW or 100 kW subunits for standalone applications.

System diagram: 50 to 350 kW EV charger

The AC-DC system comes after an EMI filter, converts AC into DC voltage and usually has a controlled rectification stage. The DC-DC conversion stage is usually an isolating type: first converting DC voltage to high-frequency AC voltage and again converting that high-frequency AC to DC voltage rectification on the secondary side of the transformer.

The common strategy in this power category is to use power modules instead of discrete devices. IGBT-based solutions featuring EconoPACK™ and EconoDUAL™ are perfect for both Vienna Rectifier and AFE, for AC-DC conversion, usually operating at around 20 kHz. CoolSiC™ Easy modules enable the AC-DC converter stage to operate at around 40 kHz to 50 kHz. CoolSiC™ is also a device of choice for the DC-DC stage to enable high switching possibility to reduce the overall system size and achieve higher efficiency.

Podcast4Engineers: Vision for eMobility: 10 kWh for 100 km

How do semiconductors ensure electric vehicles are efficient and fun to drive at the same time?

Listen to our newest Podcast4Engineers episode and join our experts Dirk and Christoph discuss how semiconductors not only enable #decarbonization in eMobility, but also ensure the “fun-to-drive” factor.

Podcast4Engineers: Fast EV charging

Today, a DC charger with 150 kW can put a 200 km charge on an EV in around just 15 minutes. As fast charging and battery technologies continue to evolve and improve in the near future, experts anticipate the charging time to drop even further. Listen to our Podcast4Engineers episodes as our Infineon experts discuss the latest trends and challenges in EV charging and how our one-stop product and design portfolio can help design energy-efficient DC EV chargers today.

Webinars

Driving decarbonization and digitalization together is crucial and the IGBT7 technology plays a major role along this entire energy chain. This training video will introduce the discrete TRENCHSTOP™ IGBT7 family and share its five decisive values and the application positioning.

In the technical introduction training, you became familiar with the full-bridge transformer driver family 2EP, which is a reliable power supply that supports Infineon’s top-notch switches and isolated gate drivers. By the end of this deep dive, you will be able to describe the working principle of this family and know about possible applications by understanding the effect of input voltage changes, transformer transfer ratio, and duty cycle changes on the isolated output voltage.

This video will introduce you to the 2EP EiceDRIVER™ power family, along with its features and advantages. Additionally, you will have an overview of the extensive application scope of the 2EP.

As electro mobility increasingly becomes part of our daily lives, the need for more efficient charging solutions is growing. With an eye on the requirements and technological developments in this field, the challenge is to respond with smart and compact power conversion solutions for the charging networks of today and tomorrow. In this webinar, you will gain deeper insights, into Infineon's comprehensive DC-EV charging portfolio with a focus on silicon carbide and its important contribution to ultra-fast EV charging.

Today's global challenges of decarbonization, combined with rising energy demand, make bi-directional electric vehicle charging and how semiconductor solutions support this application more important than ever. In this webinar you will get an overview of the power conversion topologies for bi-directional DC charging and take a closer look at an application example based on Infineon's 50 kW Reference Design.

The training overviews the different types of chargers with focus on AC EV charging and its functionality, it also positions products from Infineon for the AC chargers with focus on control, connectivity and security. The training shows block diagrams of the difference solutions.

The training overviews the different types of chargers with focus on DC EV charging and its functionality, it also positions products from Infineon for the DC chargers with focus on control, connectivity and security. The training shows block diagrams of the difference solutions.

Online Courses

In depth introduction of Infineon's one stop shop reference design for EV traction Inverter.

- Understand Infineon’s purpose in delivering quality above and beyond the standard and find out how we execute that standard in development, qualification, manufacturing and testing

- Learn where and how this high-quality standard is reflected and discover our success stories

With the growing market of electrical vehicles, the industry has put forward more requirements for the performance of charging piles. This e-learning will show you that the emergence of CoolSiC™ MOSFETs has improved the charging pile industry to make the EV charger smaller, faster and with higher efficiency.

- Distinguish the features and benefits of Infineon’s CoolSiC™ solutions in target applications and identify Infineon’s fully scalable CoolSiC™ portfolio to meet this automotive market transition

- Explain the reasons for the increasing introduction of silicon carbide technology in the automotive applications

This training covers the harmonized frame of standards from international bodies like ISO, IEC, SAE and UL dedicated to the Wireless Power Transfer system technologies.

In this online course you will learn about cost-optimized, but highly efficient electric vehicles charging solutions based on IGBT and CoolMOS™, and explore Infineon’s wide portfolio that supports every segment of the EV charging application.

This training covers the most relevant standards for high power charger design, grouped into 4 major areas:

• charging topology

• communication

• accessories

• safety and security

- The training covers detailed information about Infineon's 3rd generation automotive EiceDRIVER™ 1EDI305xAS

- Participants will learn how these products help to reduce switching losses and improve thermal efficiency, resulting in longer range for hybrid and electric vehicles

Every switch needs a driver, and the right driver makes a difference.

Infineon offers different isoalted gate driver families, such as the EiceDRIVER™ Compact and the EiceDRIVER™ Enhanced. Each family has different features to protect the switch and application.

The EiceDRIVER™ isolated gate driver offers advanced features such as reinforced isolation, Miller clamp, slew rate control and short circuit protection to protect the switch and application. It also enables condition monitoring and rapid prototyping.

The EiceDRIVER™ is the perfect fit for industrial application, particular in combination with Infineon CoolSiC™ and IGBT switches.

Training topics:

- Get to know how AURIXTM is able to answer the needs of the electric vehicle market

- Recognize and explore how AURIX™ TC3xx addresses key electric vehicle challenges, and understand the main features of the AURIX™ TC3xx microcontroller

In this training you will:

- Be familiar with silicon carbide MOSFET structures and their characteristics

- Get to know Infineon's CoolSiC™ MOSFET, its features, its improvements over a typical trench MOS and how it performs against its competitors

In this training you will:

- Get to know Infineon’s IPOSIM tool, specifically for an automotive electric vehicle inverter

- Discover the steps involved in simulating different parameters and comparing the results of different Infineon products to see which is the best fit for your application

In this training you will:

- Learn about the transition from fule injection combustion engine to full battery electric vehicles and the main 48V powered applications.

- Additionally get an overview about Infineon’s comprehensive MOSFET portfolio for 48 V applications and their support material

- Infineon's HybridPACK™ Drive silicon carbide compact power modules cater to the increasing demand for high range, efficiency, and power in electrified vehicles, enabling longer drive range, compact size, and optimized system cost.

- The second generation of Infineon's HybridPACK™ Drive, utilizing CoolSiC™ technology, offers a scalable product family with enhanced features and package improvements, providing added value to customers.

- Describe the key features and benefits of Infineon's EiceDRIVER™ isolated gate driver family and explain why it is suitable for the xEV main inverter

- List the target applications of the EiceDRIVER™ gate driver family and recall the reference designs available