Low voltage drives

Please choose a subcategory

Efficiency and control for your application

A low-voltage drive covers a voltage range from 100 to 690 Volt and power from several watts to megawatts. The drive system is connected to the grid and generates a 3-phase voltage which is variable in amplitude and frequency. This enables control of the electrical motor in torque and speed. Our broad portfolio of semiconductor modules enables you to design low-voltage drives that help to increase process productivity as well as energy efficiency, and furthermore reduce maintenance costs.

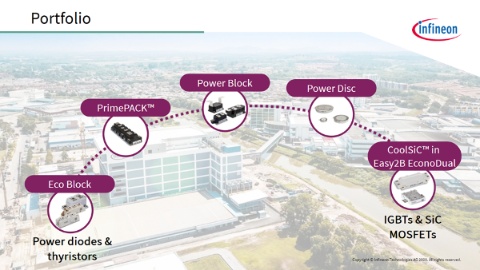

The optimal semiconductor for your industrial drive is the new TRENCHSTOP™ modules with IGBT7 technology. We offer them in Easy and EconoDUAL™ packages. For highly integrated drives CoolSiC™ MOSFETs are the best solution. By using the silicon MOSFET technology the switching and conduction losses are minimized. This enables passive cooling.For a perfect control of the power semiconductor, we offer a wide variance of gate driver ICs, such as the EiceDRIVER™ portfolio. For optimal process control, we offer microcontroller solutions based on our XMC™. We also offer memory solutions based on our NOR Flash and persistent RAM memories. A secure connection to an existing network is provided by our OPTIGA™ Trust solutions.

To select the right solutions for your applications, we offer specific overviews and exemplary block diagrams with product links on the following pages. Learn more about:

- General-purpose drives (e.g.: pumps & fans, cranes & lifts, compressors)

- Servo drives (e.g.: robotics, material handling, elevator)

Do you want to know the various topologies you can find in this power conversion stage and their top-level working principle? Get to know the basic concepts of passive and two-level active rectification methods.

This training will introduce you to how the CoolSiC™ will help to design the next generation of servo drives.

Tutorial about how to select reliable and efficient solutions regarding the requirements for industrial drives. We take a look on the key questions of power, voltage, topology, and frequency related to your application.

In this training you will:

- Understand the basics of the technology used by Infineon’s new TLI4971 current sensor

- Identify its main features, advantages, and benefits

Webinars

Servo drives come handy in a lot of applications, but controlling them and the power needed to drive them can be challenging when attempting to do it efficiently. Similarly, handling overload and short-circuit conditions is critical. Through this webinar, we will demonstrate best practices of protecting them and how to ensure the protection is reliable, robust and sufficiently fast for all operations. We will also give an exciting overview of suitable boards for evaluation and show the comprehensive Infineon portfolio of SiC MOSFETs and gate driver solutions.

Key Takeaways

- Understand how Infineon responds to the trends in the industry drives market: e.g. inverter integration with SiC MOSFETs and get an overview of some of the solutions offered

- Learn how to enable lower switching losses compare to IGBTs at same dV/dt levels and enhanced switching control

- Explore how to avoid the main pitfalls when driving SiC MOSFETs

- Discover how to reliably protect SiC MOSFETs using EiceDRIVER™ gate drivers