Hydrogen electrolysis

Efficient electrolysis through comprehensive power conversion solutions

The supply of hydrogen for industrial use is a major global business, with electrical power demand to produce green hydrogen expected to reach up to 4500 GW by 2050. Current hydrogen production, however, is supplied almost entirely by fossil fuels, consuming around 6% of global natural gas and 2% of global coal supplies. In contrast, water electrolysis can generate “green” hydrogen by harnessing renewable energy sources, such as wind and solar power. Yet, this more sustainable process is currently only responsible for around 2% of worldwide hydrogen production.

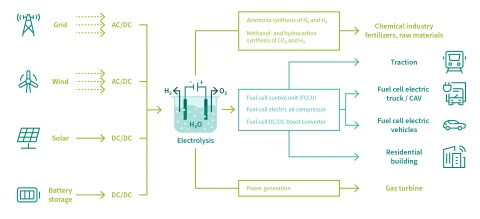

Electrolysis produces hydrogen by using electricity to split water into its hydrogen and oxygen components. The process requires high levels of direct current (DC) supplied by power conversion systems. The design of this converter significantly affects the overall efficiency, reliability, and cost of the green hydrogen plant.

AC and DC-coupled power conversion topologies, using Infineon power semiconductors, are used in large hydrogen plants. AC inputs from the grid or wind-generated electricity sources must be converted to DC for the electrolyzer. DC inputs from photovoltaic or energy storage systems must also be converted to appropriate voltage levels. A variety of power conversion topologies can be found within an electrolysis plan, including:

AFE Rectifiers:

Active front-end rectifiers are IGBT-based converters and can be operated at unity power factors and have low levels of Total Harmonic Distortions (< 5%). For systems up to 250 kW, Easy and 62mm modules are economically suited for system outputs. For those above 250 kW, EconoDUAL ™ 3, XHP™, PrimePACK™, and IHM modules are an optimal choice.

Thyristors and Diodes:

Multi-pulse thyristor-based converters, usually 12-pulse or 24-pulse topologies, are popular for AC to DC power conversion because of their robustness, high efficiency levels, and high current density. Thyristor rectifiers are particularly useful in high-power applications (>1 MW). High system power (>50 MW) can be efficiently realized through the interaction of several high-power thyristors and diode discs.

Buck Boost / DAB:

Buck-type choppers and Dual Active Bridge are often used as the rear stage of thyristor or diode rectifiers with higher power factors across a wide operational converter range.

With this webinar you will understand the breadth of the requirements that need to be met by power electronics engineers. The webinar will also present a platform approach with which common design elements can be used to create varying power conversion systems to suit all system requirements. The webinar will also include simulations and links to them for more specific designs.

Our whitepaper examines key growth drivers in the hydrogen market, highlighting the essential Power Conversion System (PCS) for electrolysis. It introduces standard electrolysis plant layouts and power conversion topologies. Infineon's leadership in power semiconductors enables a diverse PCS design portfolio. The conclusion offers insights into Infineon's product range and technological expertise.

Podcast4 Engineers - Hydrogen deep dive with Varun and Nils

As the significance of hydrogen energy continues to rise, we delve into its production process, specifically through electrolysis. Join our experts Varun Raghunath and Nils Przybilla in this episode as they explain what hydrogen electrolysis is and how power electronics help make it possible.

Podcast4 Engineers - Hydrogen on the horizon with Nils and Varun

From grey to green to blue, the spectrum of hydrogen reveals surprising color. Join our technical experts Nils Przybilla and Varun Raghunath in this episode as they explain why hydrogen is everywhere right now and how green hydrogen could change the way we think about energy.

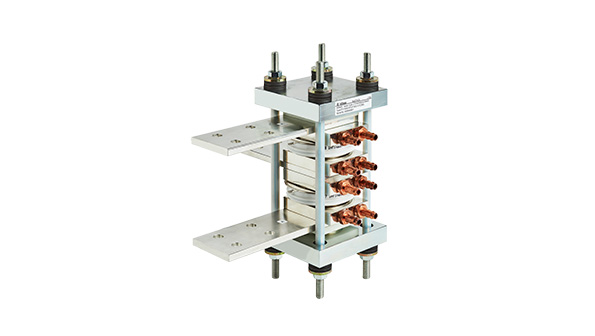

Video of photorealistic, digital 20 MW rectifier container in real-time 3D. The video shows a demo of a modular rectifier cabinet and the individual components for efficient electrolysis . Plug and Play for reliability in supply chain.

Green hydrogen is produced in a CO2-neutral manner by utilizing electrolysis processes powered by renewable energies such as wind and solar. Power semiconductors make the production of green hydrogen possible. Gain insights into AC- and DC-coupled electrolyzer applications and learn about Infineon's best-in-class semiconductor solutions.

In this training we explore the fundamentals of green hydrogen production and the pivotal role of electrolyzer technologies in this growing sector. You will gain insights into a platform-based design approach for efficient power conversion in hydrogen electrolysis. Delve into the essentials of green hydrogen production to comprehensively understand this transformative industry. Discover the diverse requirements of electrolysis plants, including technology, voltage, current, and plant configuration. Stay tuned to learn more!

Webinars

With this webinar, you will understand the comprehensive set of requirements that need to be met by power electronics engineers. The webinar will present a platform approach by which common design elements can be used to create various power conversion systems to accommodate all system requirements. The session will further include simulations and links to them for more specific designs.