Central inverter solutions

Central inverters convert power on multiple strings of connected solar panels. They are rated from around 600 kW to 4000 kW. Central inverters typically rely on single-stage power conversion, and most inverter designs are transformer-based or isolated. In the DC-AC stage, variable DC is converted to grid-compatible AC power.

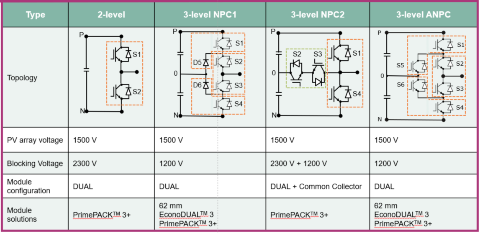

Two-level or three-level NPC1 / NPC2 / ANPC topologies are preferred in this stage. A three-level topology is widely used as it enables higher efficiency levels. A three-level NPC2 topology is usually the preferred choice for 1000 V photovoltaic (PV) systems. 1500 V PV systems are becoming more popular as they can reduce system costs and improve end-to-end efficiency. Three-level NPC1 / ANPC topologies enable more robust inverter designs more resistant to cosmic radiation. Switching frequency and cooling requirements are key factors that influence the size of the AC filter, the volume of the system, and costs. Power modules that offer low losses and high current densities are desirable.

Designers often build inverters ranging from 600 kW to 2000 kW and then connect these in parallel to create inverter solutions of up to 4000 kW. For inverter designs ranging from 600 kW to 2000 kW, our power modules enable designers to achieve best-in-class power densities and streamline manufacturing. Our products here include our EconoDUAL™ 3 family, 62 mm modules, and PrimePACK™ 3/3+ modules. And because all switches need a driver and all drivers need to be controlled, we also offer the right EiceDRIVER™ isolated gate driver along with XMC™ and PSoCTM microcontrollers to complete your inverter designs. Finally, each functional block needs a sensor and auxiliary power supply, so we offer CoolSET™ together with 1.7 kV CoolSiC™ and the TLI4971 current sensor. A smart combination to address connectivity is offered by the AIROC™ Wi-Fi + Bluetooth® Combos, which provide a Bluetooth® and Wi-Fi module in a single device.

System design challenges for central inverters

Manufacturers are continually looking to improve system costs and performance levels. As a result, inverter power capacities are gradually rising. This has led to a clear trend towards 1500 V photovoltaic arrays in utility-scale installations.

Thanks to our broad portfolio of power semiconductors and our expertise in leading technologies such as silicon (Si), silicon carbide (SiC) and gallium nitride (GaN), we can customize chip technology and packaging, offering you the perfect solution for your PV inverters.

Podcast4Engineers: Solar

Photovoltaic systems – commonly known as solar power – are driving the shift from fossil fuels and bringing us closer to having abundant, green energy. Innovative and reliable power semiconductors and inverter technologies ensure that harnessing solar power is more convenient, efficient, and attractive.

This video will introduce you to the 2EP EiceDRIVER™ power family, along with its features and advantages. Additionally, you will have an overview of the extensive application scope of the 2EP.

Let’s learn more about how solar inverters work, from the ones we have in our houses, to the ones that are applied in major factories. We will also see how Infineon innovates in power semiconductors for solar inverter technology and how that can help with reducing costs and time to market.

In this module, we will have a look at different solar inverter trends and how the technology is evolving.

And afterwards, we will see what Infineon’s comprehensive solutions for the positioning of solar applications are.