The physical principle of batteries has not changed for hundreds of years. However, the demands regarding charging times, capacity and durability of rechargeable battery systems are constantly growing. Battery Management Systems (BMS) control the power input and output of battery cells, modules and packs in order to meet modern battery requirements. This makes BMS a key component for a safe, powerful and durable battery, especially in the field of high voltage. In order to further explain the purpose and application for Battery Management Systems, we first need to take a closer look at some of the basic principles of batteries.

What is a battery?

Be it a tiny button cell in a watch, a power supply for a cordless drill or powering modern cars: for centuries, batteries have been energy storage devices that have enabled us to provide energy directly where it is consumed. The biggest advantages of batteries are the possibility of storing energy almost without wastage and the flexibility of "electricity to go", because batteries of all kinds are easy to transport. Linguistically, the word "battery" is the result of a compound. In this case, the compound is created by interconnecting several galvanic cells to store energy. Depending on the number and type of interconnected cells, each interconnection provides an individual battery capacity, the electrical charge, which is defined in ampere-hours (Ah). If a battery supplies power only once until it is completely discharged, it is called a primary battery. If it is possible to feed power back into the battery and thus recharge it, it is called a secondary battery.

How does a battery work?

Today, a variety of forms and types of batteries can be found on the market. Since the invention by Luigi Galvani in 1780, the basic principle in the operation of battery technology has not changed: An electrolyte – originally an acid – conducts ions from a base metal such as zinc to a precious metal such as copper or silver. The resulting flow of electrons enables electricity to be drawn to power electronic devices. The battery chemistry differs for the different types of batteries, for example in the battery fluid used, and thus has a great influence on the respective battery properties.

What types of batteries are on the market?

Alkali-manganese battery:

Today, most batteries with liquid electrolytes follow the aforementioned galvanic principle. From a commercial standpoint, the most successful primary battery is the alkali-manganese battery, also known as alkaline. It can be produced in large quantities at very low costs, and it is particularly useful for one-time usage, e.g. in flashlights or watches.

lithium-ion battery:

Among rechargeable batteries, the lithium-ion battery is the most popular. The term itself stands for a whole group of battery variants that allow a big number of recharges with only a slight loss of power efficiency.

LiFePO4:

The most common type of battery at the moment is the lithium iron phosphate battery – in short LiFePO4. In this version, lithium iron phosphate replaces the previously used lithium cobalt oxide. Resulting in less generated heat despite the same power density. This leads to the elimination of a self-ignition in batteries. The previously known "memory effect" has also been removed in batteries with the new material. Used as a flat design in cell phones and notebooks or as a round design in the familiar AA or AAA rechargeable batteries, the LiFePO4 rechargeable battery started its success story around the world after its invention in 1997.

Solid State Battery:

In the recent years, Solid State Batteries have been developed more and more to meet the increasing safety requirements in various industrial sectors. Due to the chemical composition and a different structure, solid state batteries can achieve a higher power density than electrolyte batteries. Combined with lower self-discharge, high robustness and higher resistance to pressure and temperature fluctuations, this technology offers major advantages over conventional batteries. However, the comparatively higher complexity of production means that the breakthrough into the mass market is still due.

High-voltage battery:

High-voltage batteries are used whenever peak performance is required. Within this type, individual battery cells are encapsulated into modules and then connected in series. This results in high-performance batteries that can supply several hundred volts. In addition to their usage in the photovoltaic context, automobile manufacturers particularly rely on this type of battery. It is usually mounted in the vehicle underbody and is also known as traction battery.

How are batteries built?

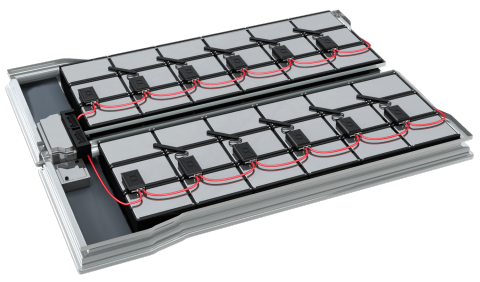

The battery structure can be defined in two ways: according to the shape of the battery cell (also: Cell Type) or according to the type of circuit (also: Integration Type). Cylindrical cells are very common. The cylindrical cell is easy to produce and withstands mechanical stress from the outside and inside very well thanks to its shape and metallic cover. For example, even when heating up, a cylindrical battery cell expands less than a pouch cell.

One disadvantage is that the round shape creates many cavities when arranged closely together, which means that the volumetric energy density of the battery pack is lower compared with other designs. In order to cope with the large number of possible variations of cylindrical cells, a standardized naming system was created. The well-known AA battery is also called a 14500 cell, according to this regulation. The first two numbers describe the diameter, the remaining three numbers the length of the cell in millimeters. Following this logic, there is also the less commonly known 18650 lithium-ion cell, for example. With a diameter of 18 mm and a length of 650 mm, it is produced often and also used in electric cars.

Pouch batteries solve the packaging space problem. Here, the components are not arranged cylindrically around a core, but rather stacked in the desired layout, pressed and finally laminated in an outer shell containing aluminum. This pouch variant offers great shape flexibility and a big power density at low weight. To that effect, it is susceptible to mechanical impact. Under heavy stress and with increasing lifespan, a pouch cell inflates by three to ten percent – an effect that must be taken into account in the design of surrounding components.

Prismatic cells are also known as flat cells and are characterized by their large total surface area – resulting by folding thin layers. The prismatic cell offers very good thermal behavior and is encased in a solid metallic housing to withstand mechanical stresses. The combination of high robustness and good use of installation space makes this form particularly popular when building electric cars.

Automobility puts high demands on the performance of a battery. To meet these requirements, the performance of the individual battery cells is scaled via intelligent connection. Mounted in series or in parallel, individual cells form a battery module. These modules provide sufficient power for household use – in vacuums, cordless screwdrivers or e-bikes, for example.

For a further increase in power, several battery modules are combined to form a battery pack. This produces enough power for an energy storage system at home, for a forklift truck or even for cars. In the Jaguar iPace, for example, 12 individual cells are combined in 36 modules to form a battery pack. The high operating voltages require an optimally coordinated control system – from the individual battery cell to the seamless interaction of the battery packs. Based on the requirements for batteries in cars, a Battery Management System plays an increasingly important role for the efficiency and longevity of their high-voltage batteries.

What is a Battery Management System (BMS)?

In lithium batteries, the key to longevity, efficiency and reliability lies in the permanently optimal interaction of the individual cells, modules and packs. The main task of a battery management system (BMS) is to protect the battery against faulty operation and to optimize the charging and discharging processes. An active battery management system relies on several components at the same time and thus becomes a smart BMS. The advantages of an Active Battery Management System: It monitors the aging and charging status as well as the depth of discharge of the battery modules. It controls the charging cycles smartly and optimized in regard to speed, thermal management or overcharging.

Fields of application for Battery Management Systems

An intelligent battery management system always shows its strengths when it comes to dynamically changing requirements in power supply in combination with the longevity of lithium battery systems. This is the case, for example, in the field of building technology for the control of energy-generating and -recovering systems. Optimal control of charging speed, processor performance and battery temperature are also relevant in the field of mobile consumer electronics and communication technology.

The requirements for a battery management system are particularly high in the automotive sector. In addition to extreme fluctuations in power consumption and output, the uninterruptible power supply (UPS) must be ensured. Especially when driving and charging in the heat of Las Vegas or in the arctic cold of Norway, the uninterruptible power supply of system-critical components sets high challenges for an automotive battery management system.

The deep integration of the e-car battery into the vehicle infrastructure also makes intelligent charge-handling indispensable – so that the installed battery lasts for a long time. While charging an electric car, a charging protection system in the BMS prevents too much power output into the battery, which could lead to thermal instability of the e-car battery or irreversible chemical reactions. At the same time, as part of the discharge protection, the Automotive Battery Management System ensures that the cells are not used if their capacity was almost completely exhausted. Such a deep discharge shortens the lifetime of lithium cells enormously and could even destroy them in extreme cases.

What is the benefit of Battery Thermal Management?

Battery Thermal Management is a central component of a smart Battery Management System. It perfectly controls the energy flow within the battery system based on the surrounding ambient and battery temperature. Lithium batteries only work ideally in a temperature range of 20 to 30 degrees Celsius. Thanks to thermal management in modern vehicles, however, they can still be charged very well at outside temperatures of 0 to 40 degrees. Optimally controlled, they also release their power between -20 and 60 degrees Celsius outside temperature without suffering any damage.

Battery thermal management keeps the operating temperature within this range by controlling the cells intelligently. Battery operation beyond these limits quickly has a critical effect on the lifespan, the possible charging cycles and the capacity of the battery cells. Optimal thermal management in an electric car is particularly important. Due to its deep integration into the vehicle's infrastructure, replacing a defective e-car battery is very expensive, and overheating or even ignition of the battery has serious consequences for the entire vehicle. Managing thermals with a smart Battery Management System not only contributes to the longevity of batteries, but it is also essential for everyday safety.

Innovations in the field of Battery Management Systems

Much has happened since the development of the lithium iron phosphate battery (LiFePO4) in the 1990s. Many innovations are currently being developed worldwide, particularly in the field of battery management types (BMS types).

So-called AI BMS (Artificial Intelligence Battery Management System) introduce self-learning algorithms to the battery. Fed by Big Data, the battery obtains information to optimize its range. EIS (Electrochemical Impedance Spectroscopy) is used to mathematically monitor the health status of a battery. This helps to estimate the performance of the cell during fast charging and enables the early detection of cell damage. With the Infineon already offers a series product with these capabilities today.

Programmable Battery Management Systems (Programmable BMS) are designed to monitor and evaluate battery data such as temperature values, cell health information and performance data. In the future, a Wireless Battery Management System (Wireless BMS) will link the cells with each other via radio: This means fewer cables are needed – which saves weight and can also bridge difficult-to-access areas with ease.

The future of intelligent battery management has only just begun. Infineon is actively shaping this development and already offers industry-leading solutions today. Our solutions for use in automotive, photovoltaic and consumer products are clearly arranged in the Battery Management Systems section.

Last update: September 2021