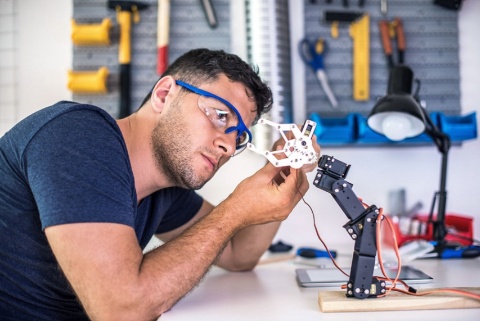

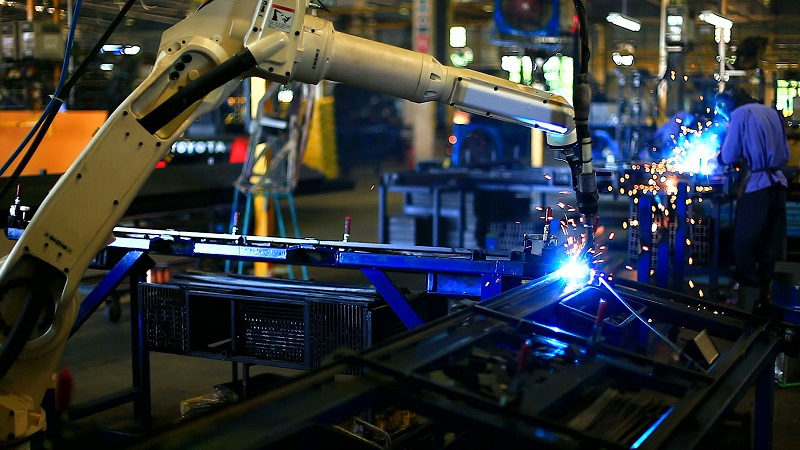

With automated machines and robots now commonplace in most factories, it would be easy to think that they would run until the electricity is turned off. However, it falls upon technicians and engineers keeping everything up and running.

Like our cars, most manufacturing equipment comes with some sort of servicing schedule. According to statistical service predictions, after a set number of hours of use, the machine will need to be oiled, have parts replaced, and important elements will require inspection. Sometimes, these inspections will be fast and simple. Other times, they may require many hours of work and (sometimes) expensive parts are to be replaced in order to avoid any later unexpected break-downs.

Depending on the type of usage, the intervals between these scheduled services could vary. A robot arm that regularly lifts one ton cast metal parts is likely to suffer more wear than the same robot arm that only lifts half that mass or moves much slower.