Optimized semiconductors open up new degrees of freedom, as they let robots interact with humans outside a cage. For this type of collaboration, however, these robots – also known as cobots – have to fulfill certain design criteria.

By courtesy of Hüthig Publishing House

Cobots support humans in factories

Robots have long become the workhorses on production lines in modern factories. Manufacturers worldwide benefit from improved productivity and improved costs. Against the backdrop of Industry 4.0 and the smart factory, traditional production processes are now being revolutionized by the latest generation of industrial robots, know as collaborative robots or ‘cobots’. They work together with people, support them in the respective manufacturing processes, and improve the quality of the finished products thanks to their high level of precision and safe way of working. Infineon offers an extensive range of components, from controllers and power electronics to sensors and chips for safety and security functions, for implementing the efficient electronics of this new generation of robots.

Unlike conventional industrial robots, cobots operate without safety cages and interact with directly humans. To meet the requirements this entails, their design must include specific features. Special security measures are required in particular so that robots and people can work together safely.

The key design criteria for cobots are:

- High power density and a controller with as small a form factor as possible

- High precision, integration and efficiency

- Functional safety and protection of humans in the area

- Different topologies regarding the number of axes, joints, and motors

- Protection of intellectual property against counterfeiting

- Security as a prerequisite for safety

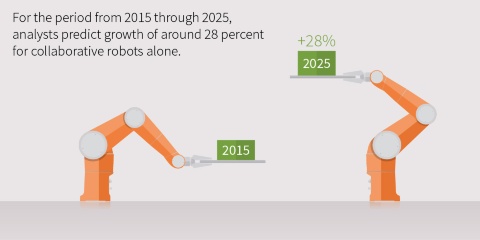

These requirements can be implemented in the development of traditional robots, industrial robots, and the aforementioned collaborative robots with intelligent and efficient semiconductor solutions. And the market offers a lot of potential. In 2015, revenue in the industrial robot market reached almost 10 billion U.S. dollars worldwide. For the period from 2015 through 2025, analysts predict growth of around 28 percent for collaborative robots alone.

Robots and their application at Infineon

Infineon produces not only a comprehensive semiconductor portfolio that is used in robots, but is itself a user of various generations of robots. Since the equipment used in chip production is very expensive, the focus here from a very early stage was on optimized automation to maximize machine utilization and be able to constantly monitor and readjust production quality. The yield can thus be increase and best use made of cleanroom facilities. Many concepts currently being discussed in Industry 4.0 are already in use here, such as fully connected production. Mobile robots, known as AGVs (automated guided vehicles), also ensure the integration of previously autonomous production islands. In addition to the robots within the production islands, more than 170 mobile robots work at the production facility in Dresden alone. The resulting robotics systems expertise is then incorporated again into the development of the chip.

New type of robot: compact, agile, safe and secure

Technological advances in the fields of sensor technology, rapid analysis huge data volumes, artificial intelligence, and power electronics have made the new generation of robots possible. The robotics market is in transition. Alongside the well-known top dogs, many relatively small start-ups have appeared on the market, and the trend is continuing. Their focus is on developing special algorithms as the basis for new robotics concepts. Since they are less interested in the mechanical design and the required electronics hardware, they depend on suppliers with systems expertise and corresponding products. This enables the specialized new robotics start-ups to build, within a matter of weeks, development platforms that form the basis for robots that can be used in a wide range of fields. They don’t require expensive programming for each target application as with earlier generations of robots. Instead, they are simple and flexible to reprogram, and can adjust their motion sequences – sometimes even autonomously – to new requirements.

Semiconductor portfolio for modern robots

The new generation of robots offers a broad field of application for modern semiconductor products. This ranges from motor control, powerful position and object detection, efficient and compact drives, power supply and chargers, and the implementation of virtual safety gates to security functions with secure authentication and calibration. In connected production environments, functional safety is not possible without security. Also essential is the protection of intellectual property, especially for start-ups whose expertise lies in algorithms.

Another key criterion for the new generation of robots is as compact a design as possible, in particular a space-saving and efficient motor controller. This is achieved with IGBTs and IGBT modules, MOSFETs with low on-state resistance (such as OptiMOS) and highly integrated gate drivers with built-in protection functions. Ensuring functional safety is also an especially important aspect. Parameters like torque, position, pressure, etc. need to be captured precisely with corresponding sensors and the data processed with powerful safety controllers like the AURIX family.

Escape the cage: protection for human

If you want to liberate robots from their cages, you must make sure that humans cannot enter the critical reach of a robot operating at high speed in the first place and be injured, either through their own negligence or a malfunction. Making robots sufficiently sensitive only works with sophisticated sensor technology.

Basically, the area between humans and robots, but also between the robots themselves must be made safer. The aim is to make protection zones more flexible so that, for example, a much smaller protection zone moves dynamically with a moving robot arm. A zone concept is used to implement the virtual fences. If a human enters the outer perimeter, a warning signal is emitted, but the robot continues to operate at full speed. If the human gets closer, the speed is reduced and a warning is issued accordingly. The robot only stops if the human is directly in the danger zone.

Such protection mechanisms require extremely precise object detection capabilities. Redundant scanning provides maximum functional safety. Detecting the direction of movement is also helpful – is a person approaching and then moving away again, or entering the danger zone? By intelligently recognizing the actual threat situation, unnecessary robot downtimes or slowdowns – and hence production losses and costs – can be avoided.

Infineon is working in this context with partners on time-of-flight (ToF) concepts and with radar sensors. The environment can thus be scanned in 3D at more attractive system costs than with traditional lidar scanners. The 3D resolution enables the direction of movement, for example, to be anticipated through the use of special algorithms. The Dresden plant is already working with a robot prototype that recognizes its environment with ToF 3D cameras and, as a result, will then also anticipate directions of movements. A redundant expansion to 24 GHz and 60 GHz radar systems is being prepared.

Safety and security

Although both terms, safety and security, sound similar at first, there is a clear distinction: While safety deals with the protection of human, security embraces data protection and thus aims at protecting robots from cyber-attacks. Only systems that are safe in terms of data security are also functionally safe – an aspect that is becoming increasingly important in the context of Industry 4.0 and IoT. Encryption systems must ensure that the robot executes only those functions it should. In this case, the aim in particular is to protect the robots as part of the production process against manipulation during wired or remote software updates. Secure authentication of users and newly added components is also required.

To function correctly, robots must also be calibrated. However, if a hacker manipulates the calibrations, for example, the robot could exceed its programmed motion limits. This is where safety and security converge – without efficient security protection, there is no functional safety. This is a key requirement for future systems and is being addressed by special security controllers (OPTIGA family) or AURIX microcontrollers with functions such as HSM (hardware security module). Since the security functions are implemented in the hardware, users need only minimum detailed knowledge of encryption technologies. In addition, the impact on existing software implementations is extremely low.

Longer mobility

Efficient and compact power supplies and charging functions play an essential role in mobile robots. Based on state-of-the-art CoolMOS, SiC and GaN technologies, Infineon expects the power density to increase by a factor of 2 to 5 compared to conventional battery chargers with a shorter charging time for mobile robots. Cordless charging is also possible. Power can be used even more efficiently if the batteries are recharged during the braking process (recuperation). Modern power semiconductors make this possible, as does better use of the batteries in uninterruptible power supplies, for example, for power buffering. As more and more battery-powered AGVs are used in future Industry 4.0 factories, they could be connected to drastically reduce the costs for the additional UPS batteries required in production. That’s because the batteries of an AGV being charged can to some extent be used to supply emergency power to the plant’s internal grid.

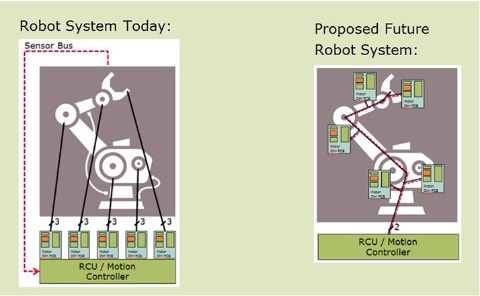

Simpler cabling

A traditional industrial robot is usually based on a central motor controller and a host of drives in the axes. That requires a considerable amount of cabling for a typical robotic arm with thick 3- or more-phased cables per motor plus an additional communication bus for control purposes and to read sensor data.

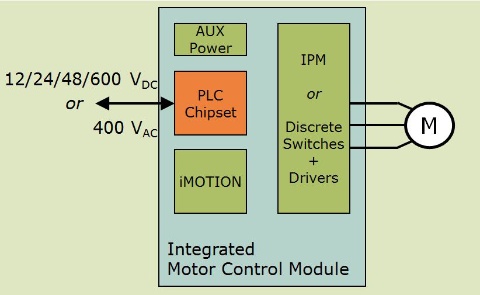

Thanks to modern semiconductors and the integration of power line-like modulation (power line communication (PLC) technology) paired with motor control electronics, the amount of cabling can be reduced considerably, hence also weight and costs. In laboratory tests, Infineon managed to cut the number of cables in a robot arm from almost 30 to just two or three. At the same time, transmission speeds of well over 100 mbps were achieved, which is almost real time. Fewer cables also means fewer interfaces in the harsh industrial environments, which improves reliability. A first prototype of such a motor control system, for which Infineon is integrating the necessary components, is currently in preparation.

A corresponding PLC chipset (12, 24, 48, 600 V DC or 400 V AC) that has been optimized for the existing power electronics will be integrated into the inverter modules. The integration of PLC technology and the higher power density of the motor electronics enable locally controlled motors to be fitted with ease directly into the robot’s axes.

Efficient maintenance

Systems for Industry 4.0 applications also require efficient predictive maintenance. The status of the motors, their controllers and the entire system must be scanned in a non-invasive manner by monitoring voltage, current, frequency, temperature, pressures, noise, gases, etc. This data must then be processed and compared with reference values on the basis of machine-specific algorithms and sensor values. The right monitoring can reduce downtimes and lay the foundation for Industry 4.0.

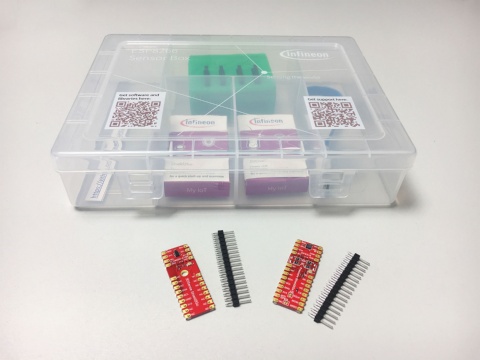

Infineon has developed a special sensor box for such applications that is connected to a PC via Wi-Fi or USB. Each box can accommodate up to two sensors in the form of what are known as Arduino shields. Up to four boxes can be connected via a USB hub to a total of eight sensors such as silicon microphones, and pressure, current, angle, CO2, radar, and magnetic 3D sensors. Based on the broad sensor portfolio, this solution enables interested customers to make the best sensor selection for their monitoring function and simply develop their own algorithms for each desired application.

Summary

There is a growing demand in the field of robotics for smaller controllers, intelligent safety measures for collaborative and non-collaborative environments, support for constantly changing work environments and tasks, and improved security functions to protect against manipulations and hacker attacks. The ongoing robotics revolution has brought forth a new type of robot, what are known as collaborative robots. These interact directly with humans, who can work alongside them without the need for locked safety cages. Since they feature advanced sensor and control components that limit their power and force in order to completely eliminate critical collision situations, they meet the highest safety requirements. Modern microcontrollers with safety functions, fast and precise sensors, and efficient power components breathe life into the new generation of robots for safe working with and not just for humans.

Last update: April 2018