ASIC

ASIC subcategories

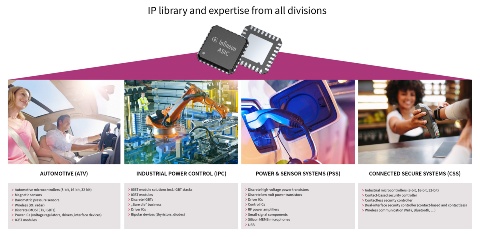

Infineon customized solutions for a wide-range of applications

An ASIC (Application Specific Integrated Circuit) or CSP (Customer Specific Product) is a custom IC that is designed, planned, developed, and used for a specific purpose, with the mission of being optimized, efficient, and having all the required functionalities and features to be used in a specific application for a single customer. Infineon has been a leading supplier of ASIC chips and all related services for more than 40 years.

These fully customized IC solutions enabled by Infineon’s extensive knowledge, experience, and manufacturing network, provides several more advantages for ASIC manufacturers, such as optimized partitioning, IP protection, trusted Infineon quality and proven supply guarantee.

Already have an idea or a project you would like to share with Infineon? For customized solutions please contact us.

Custom ASIC chips - efficiency, expertise, and experience from start to finish

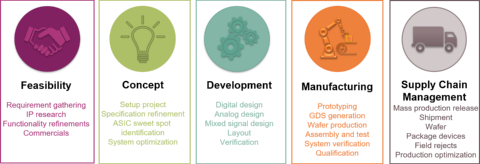

The journey begins with a focus on feasibility and early concept where we match your needs with our deep system knowledge and ASIC developing expertise in building world-class industry-leading semiconductors, ensuring we can successfully implement your requirements.

Customer is always in focus and Infineon targets long-term relationships between us as ASIC supplier and manufacturer and you as our valued customer. We do not want to build just one ASIC for you. We commit, we partner, we innovate, we perform.

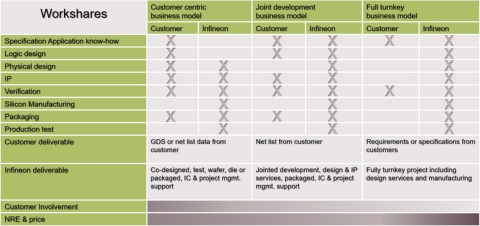

We offer multiple different working and business models which can be tailored explicitly to meet customer needs. If you have no ASIC semiconductor design team and lack the capabilities to develop this type of custom IC, we can offer a full turnkey ASIC design solution. If you have an experienced design team and want to contribute significantly during the development of your ASIC design, even with your own IP, we can select a customer-centric working model to suit you.

We have 56 R&D locations worldwide with competent ASIC customer and design service centers for various applications. Click here to see the R&D locations.

The journey begins together with a focus on feasibility where we match your needs with our 40 years of expertise in building world-class industry-leading semiconductors. We look in-depth into your application and requirements to see how we can best fulfill your needs. We can take care of everything for your ASIC during the entire custom chip design from project start through ramp-up and production.

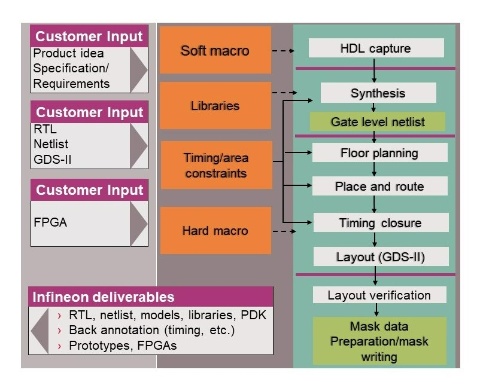

When it comes to the development of an ASIC or an embedded system, the first step is the product idea. Just tell us what you need.

Product idea examples can be:

- The modification of an existing standard product to be optimized for your system

- The integration of several functions of one or more existing off-the-shelf products

- An existing FPGA (with or without modification or enhancements)

- A list of ASIC requirements for your system

- An ASIC specification with details of the integrated functions

You can access a numerous number of IP and ASIC technologies we possess, from industrial to medical ASICs, consumer ICs, wide-band-gap, or standard silicon and much more. We always look beyond ASIC products and have your entire system in mind. Multiple products or application features that can be optimized include:

- Performance

- System cost

- Power (from ultra-low to high)

- Thermal requirements

- Efficiency

- Form-factor

- and more…

In this phase, we define the detailed concepts of ASIC integration, including implementation, project setup, and timeline. ASIC packaging and technology will be fixed, and we can decide if we will go for a single silicon solution (SoC = System on Chip) or a chip that includes multiple dies (SiP = System in Package).

As a market leader in customized solutions, Infineon believes innovation is born through collaboration and exploring new paths. Working closely with our customers, understanding their needs, and implementing with our cutting-edge solutions, we know there are always opportunities for every customer. Our customers have benefitted from our drive to come up with new ideas, think ahead, and solve problems before they occur. We have an eye for detail and as one of the leading ASIC semiconductor companies in the world, we design ASICs that excel and lead.

In ASIC turnkey projects, an ASIC specification will be developed based on your idea, which will later be aligned with optimized partitioning for the IC, always taking your system requirements into account. We offer a vast range of innovative ASIC solutions and services to help drive your system efficiency further and improve overall cost-effectiveness.

In customer-centric or joint development projects, we partner and build a combined team of R&D resources that will execute the ASIC design flow for the entire project. We encourage you to bring in your design expertise, some smaller IP-Blockup to a complex analog block including physical design tasks. We define a statement-of-work for every project, which will be tailored to individual customer needs to ensure smooth execution.

Our goal in system understanding continues throughout the development phase of your ASIC design and it is important for us that strong communication is maintained with our customers throughout the entirety of this process. Customers can take advantage of Infineon’s core competencies in combination with world-class analog mixed-signal ASIC design flow expertise, power, RF, security, embedded control, and sensor integration to achieve the product or solution needed in the shortest time possible.

Infineon’s ASIC design flow is a highly automated approach applying state-of-the-art deep submicron design methodologies, such as early floor planning, links-to-layout, timing-driven placement, and routing. The “first-time-right” claim is backed by design-for-test measures such as full scan design, ATPG (Automatic Test Pattern Generation), BIST (Built-in Self-Test), macro isolation with boundary scan, IDDQ testing, etc. Tight time-to-market cycles are met using advanced verification methods, such as static timing analysis, formal verification, and well-defined sign-off procedures for all ASIC technologies.

For the various ASIC design steps, we use industry-leading, commercially available tools. Our emphasis on standard interfaces and tools simplifies integration with the customer design flow tremendously. We ensure continuous learning on ASIC design flow and technology and implement regular updates of our design system and libraries based on the latest silicon results. Existing FPGA can be converted to an ASIC in an easy and automated way using our conversion tools. After the assessment, additional functionality can be integrated as well, if needed.

Infineon is globally positioned with its network of 20 owned frontend and backend manufacturing sites. We also have well-established partnerships with all major silicon foundries and assembly and test fabs to complement our in-house technologies.

Our customers can concentrate on their core businesses while Infineon takes care of production stability and continuity. This saves our customers a lot of resources and minimizes risk. We deliver only the best-in-class ASIC products to our customers. All of our products have passed extensive qualification and reliability testing before production. The qualification plan will be aligned with our ASIC customers and will exactly match their requirements while fulfilling Infineon’s highest quality standards. Our goal and initiative is zero defects.

Our cutting-edge fabrication facilities around the globe are advanced, innovative, and known for the highest quality standards. We align with our customers on the forecast and required capacity to ensure no supply bottle necks occur. Our global distribution centers for ASICs and standard products are always close to customers and ensures that devices will reach the customer in the fastest possible time.

Infineon understands the entire supply chain and ensures materials will reach the next manufacturing plant before the reserved slot starts. We automatically plan backup lots and install certain buffer stock to always maintain supply without interruption. This ensures for the reliable delivery that Infineon is known for and is valid for full custom ICs as well as for standard products.

Working with Infineon from design through to delivery

Infineon as a market leader in customized solutions believes innovation comes through collaboration and exploring new paths. Working closely with our customers, understanding their needs, and combining with our cutting edge solutions, we know there is always a benefit for every customer.

Whether the challenge is related to IP, BOM Constraints, or simply requiring higher integration, an ASIC can be the solution. We have access to a huge library of IP which can be used as building blocks for new ASICs.

Whether it’s digital, analog, mixed-signal ASICs, an embedded processor, or integrated sensors - we have the experience and product know-how.

Being one of the largest ASIC semiconductor companies, we also have a huge library of IPs. We can integrate almost anything into your chip from the vast variety of our sensors, discrete devices, drivers and much more.

If the challenge is related to protect your IP, reduced system costs, higher performance, or simply the need for higher integration, an ASIC can be the solution.

Infineon ASIC’s or Customised solutions can be used in a wide range of applications. See below only a small representation of such applications supported.