Advanced Isolation

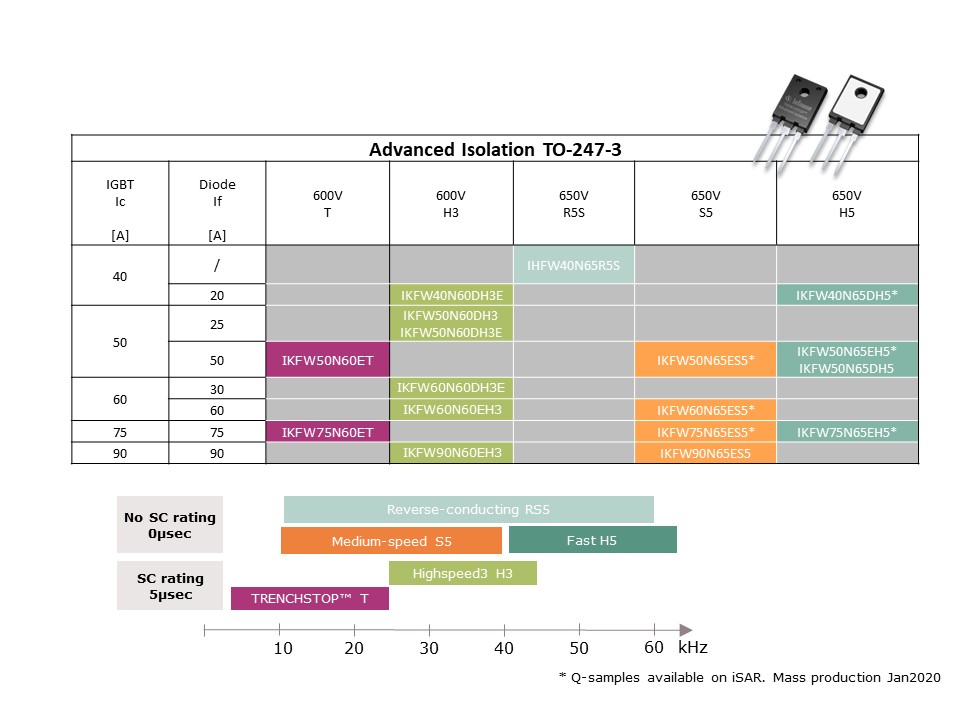

TRENCHSTOP™ Advanced Isolation - Fully Isolated TO-247 Package with TRENCHSTOP™ IGBT3

Design flexibility, high output power, low cooling effort, high reliability and electrical isolation.

Having to find the right compromise among all these conditions has limited engineers designing power electronics systems for major home appliances and industrial applications using discrete IGBTs for years. The solutions available in the market, like fully insulated packages (Full-Paks) and discrete IGBTs with iso-foils or ceramics, have proven to be expensive, low performing, difficult to handle and inadequate for heat dissipation needs of the last generation´s high power density chips.

Exclusive Advanced Isolation Whitepaper

Your exclusive insight on the new 600 V IGBT 3 TRENCHSTOP™ Advanced Isolation TO-247.

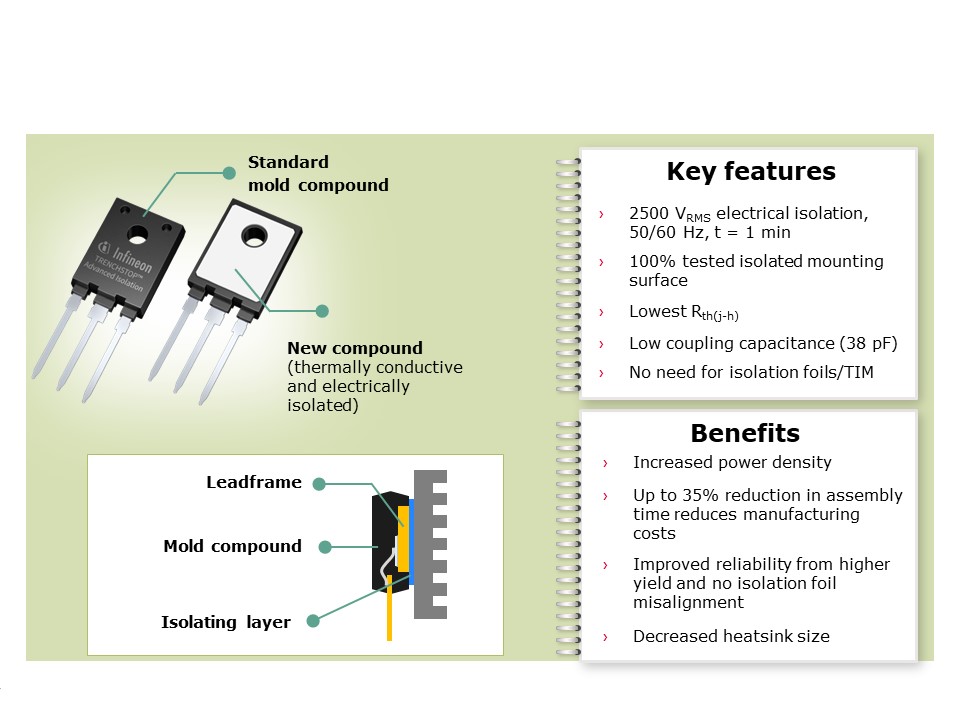

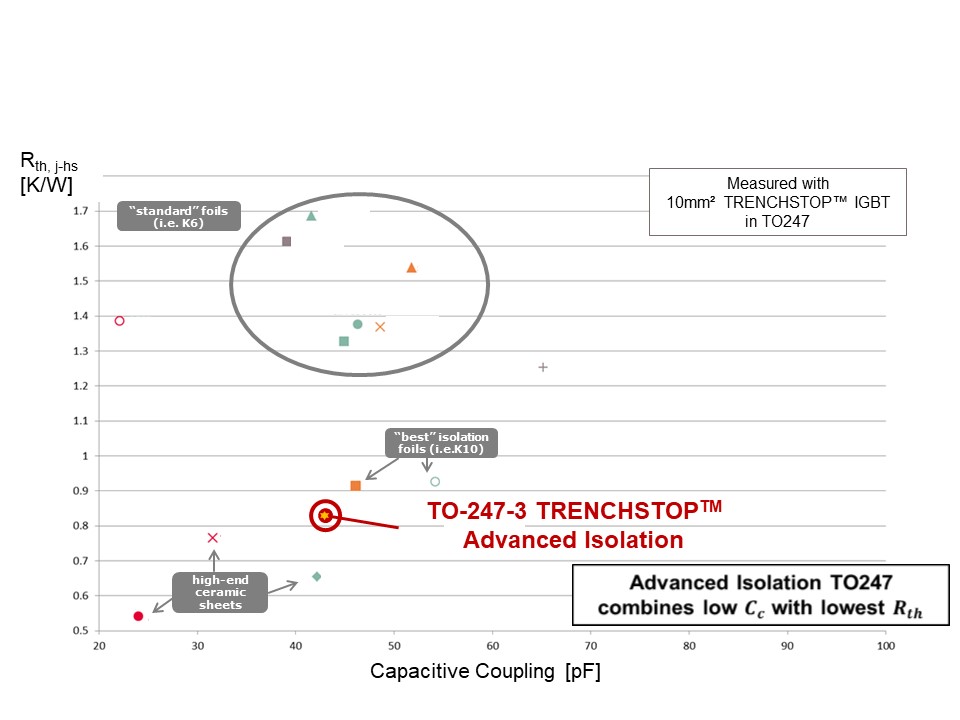

Conventional options for isolation like fully isolated packages are easy to assemble but have high thermal resistance.

The new Advanced Isolated TO-247 fully encapsulated package with low thermal resistance eliminates the need to use isolation foil or thermal grease, thus allowing reduced assembly times still providing highly reliable isolation.

> Interested? Check out your exclusive Advanced Isolation Whitepaper!

The TRENCHSTOP™ Advanced Isolation represents Infineon´s answer to the limits reached by traditional packaging and isolation techniques. This new isolation package enables the highest power density, the best performance and the lowest cooling effort thanks to an effective and reliable thermal path from chip to the heatsink.

This package concept is able to match the highest requirements in terms of performance, design flexibility and ease of handling. By eliminating the need for thermal grease or thermal interface sheets the TRENCHSTOP™ Advanced Isolation is able to deliver at least 35% lower thermal resistivity and at least 10% system cost reduction, helping designers to lower system complexity, development time, and assembling costs.

TRENCHSTOP™ Advanced Isolation represent the cutting-edge technology in isolated packages and eliminates all the boundaries and constraints that until now have limited the designers’ ability to realize more powerful, more compact and highly differentiated systems.

| Key features | Key benefits | Applications |

|---|---|---|

| Fully Isolated package

|

Lower assembling costs

Improved reliability

|

Uninterruptible power supply (UPS) Industrial heating and welding

|

| Best-in-class Rth(j–h)

|

Decreased heatsink size or Increased power density

|

|

| Low coupling capacitance

|

Decreased EMI filter size & decreased system costs | |

| 100% package test

|

Improved reliability

|