SPIDER+ LED

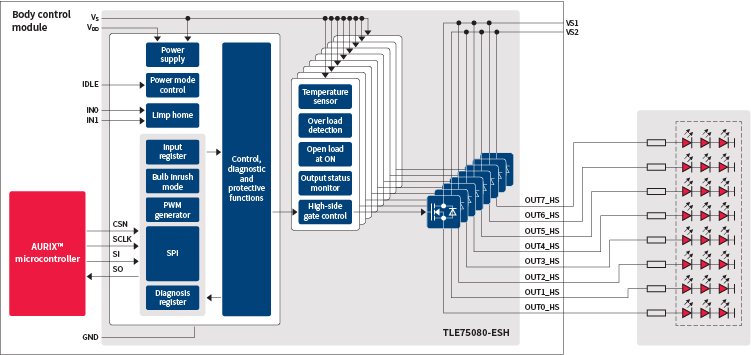

SPIDER+ LED devices combine the feature set of the SPIDER+ family with additional features to drive small bulbs or LEDs

Besides one high-side channel device, three configurable devices support LED designs in the most cost-efficient way with diagnostic and protection features.

- 4 and 8 channels

- 16-bit SPI interface

- Up to 330 mA with all channels ON

- Overload protection

- Open-load detection at OFF

- Overvoltage protection

- Overtemperature protection

- Short-circuit protection

- AEC qualified

- Limp Home mode with IDLE & IN pins

- Bulb Inrush Mode (BIM)

SPIDER+ LED product portfolio

All SPIDER+ LED devices are pin-to-pin compatible with the standard version.

In addition to the standard features already described, the LED pack enables the next functionalities:

- Open-load diagnostics in the ON state – with open-load diagnostics in the ON state, undesirable LED glowing in the OFF state is removed. A diagnostics loop is also available so each channel is diagnosed automatically in synchronization with its control signal, including PWM, reducing the workload of the microcontroller to a simple SPI command.

- Two internal PWM generators – in addition to the two direct input pins, with the two internal PWM generators, up to four different PWM frequency and duty-cycle combinations can be used by the output drivers.

- Bulb Inrush Mode (BIM) – BIM is an auto-retry feature that enables the device to handle inrush currents that would normally latch the output OFF. With BIM, driving small bulbs up to 5 W or other capacitive loads is also possible.

Automotive applications of SPIDER+ LED

The most common automotive application for SPIDER+ is in the body control module (BCM) arena, where a high number of relays, indicators, and actuators distributed throughout the vehicle are controlled and diagnosed. However, SPIDER+ serves almost any automotive electronic control unit (ECU), for example, power distribution box, HVAC flap control, smart mirror control, e-shift, steering wheel vibration (lane change alert), and many others. For SPIDER+ LED devices, the focus is on LEDs and small bulbs as the devices include Bulb Inrush Mode.

Industrial applications of SPIDER+ LED

The most common industrial application for SPIDER+ LED is driving relays, indicators, and actuators in white goods electronic control units. The SPI communication interface allows the user to reduce the pin count of the microcontroller. This results in system cost savings and more precise diagnosis and protection. The Bulb Inrush Mode feature can be used to easily supply capacitive loads such as other ECUs, removing the need for fuse protection.

| Applications | Key features |

|---|---|

|

|

- Up to 8 Channel with one device or 4 channel per battery feed - can support left and right real light with basic function like break, tail, indicator

- Full diagnostic for proper analysis of light status

- Excellent protection to support wire harness reduction - smallest possible diameter can be used!

Infineon Developer Community is available 24x7 for you to connect and network with engineers across the globe. Get help from Infineon support engineers, and expert members to solve your design challenges anytime, from anywhere, in any topic, and in your preferred language.

•Understand the SPIDER+ family and the main features

•Apply an example load to the device and show how the device reacts to SPI commands

- Get to know the main features of the SPIDER+ family and how it can improve system performance

- Discover its various applications, from industrial to automotive and learn about the advanced features of the LED pack

- Understand the different LED driving concepts

- Get to know the Infineon solutions regarding automotive rear LED lighting

- Recognize Infineon’s set of LED driver families for automotive rear lighting

- Apply Infineon’s chip-set in a conventional rear lighting architecture and its extension for dynamic effects

- Understand the different LED driving concepts

- Get to know the Infineon solutions regarding automotive rear LED lighting