Infineon launches SECORA™ Pay Green – the world’s first contactless payment card technology allowing for up to 100% reduction in plastic waste

- SECORA™ Pay Green paves the way for a more environmentally responsible future in the payment industry

- The eco-friendly Coil-on-Module (eCoM) package allows the use of recyclable materials and a recycling share of card bodies of up to 100% while reducing CO 2 in raw material sourcing and logistics by more than 60%

- Infineon is collaborating with major card manufacturers and payment schemes worldwide to ensure readiness

Munich, Germany – 16 October 2024 – Infineon Technologies AG (FSE: IFX / OTCQX: IFNNY) is paving the way to a significant reduction of plastic waste and CO 2 emissions in the payment card industry. The company today announced the launch of SECORA™ Pay Green which enables card designs allowing production of the world’s first fully recyclable contactless (dual-interface) payment card bodies based on environmentally friendly and locally sourced materials.

Activities relating to SECORA Pay Green will create the catalyst for initial pilots with issuing banks. Additionally, Infineon is partnering with leading payment card manufacturers and payment schemes in preparation for mass production. As the industry moves forward, the successful execution of first pilots will be instrumental in driving the adoption of eco-friendly payment cards.

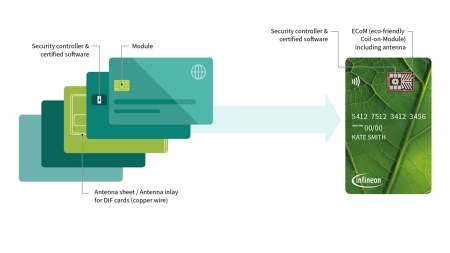

Infineon’s SECORA Pay Green pioneers a new generation of payment card technology. Conventional payment cards require embedding a separate copper wire antenna in the card with various material layers, including inlay foils. These layers and the copper wire antenna that spans the entire card make it almost impossible to easily recycle conventional contactless payment cards. In contrast, Infineon’s new SECORA Pay Green solution sets a new standard for the recycling of dual-interface payment cards by combining the new eco-friendly Coil-on-Module (eCoM) package, which holds the security controller and all software components and integrates the contactless antenna. At the end of the card’s service life, the complete eCoM package can be removed from the card and disposed of as electronic waste. The homogeneous card body can then be recycled as plastic, wood or paper, depending on the material. The integration of the antenna also saves costs and emissions associated with the transportation and sourcing of copper wire for conventional payment cards. The new module design results in more than 60 percent savings in CO 2 emissions connected to the sourcing of raw materials and logistics. Using the innovative eco-friendly eCoM module, SECORA Pay Green reduces emissions to 27.10 kg CO 2e* per 1,000 cards manufactured compared to 90.08 kg CO 2e for standard card systems.**

“As a leading semiconductor company in power systems and IoT, Infineon is committed to driving decarbonization and digitalization,” said Thomas Rosteck, Division President Connected Secure Systems at Infineon. “Our SECORA Pay Green launch not only sets a new standard for sustainable payment cards; we are also paving the way for a more environmentally responsible future in the payment industry. By reducing CO 2 emissions and enabling easier recycling, we’re empowering financial institutions and card issuers to positively impact the environment while meeting customers’ increasing demands for eco-friendly solutions.”

“Since 2018 Mastercard and industry partners have been working together developing better, more sustainable card options. Current product offerings have proven that payment cards can be manufactured with improved recyclability from renewable sourcing,” said Joe Pitcher, Vice President Mastercard Sustainable Card Program. “We support innovations like Infineon’s SECORA Pay Green that demonstrate innovative thinking and a willingness to re-engineer products, to reduce their environmental impact. Mastercard encourages vendors to pursue more ambitious emissions reduction goals, and innovate their product portfolios, like Infineon.”

“This new Infineon chip is a game changer for the card industry,” said Toni Thompson, EVP Credit and Debit Solutions at CPI. “As a leading card producer, CPI has a long-term strategic relationship with Infineon. We’ve already begun incorporating this new chip into our wide range of card materials designed to help our clients stay top-of-wallet with their accountholders. The SECORA Pay Green chip further enables our shift towards even more eco-focused options while continuing to deliver convenience and innovation to our customers.”

“One of Perfect Plastic’s missions is to find renewable and recycled products for card manufacturing,” said Mike Sabatini, Senior Vice President Manufacturing, Perfect Plastic Printing. “Our continued partnership with Infineon has enabled us to find these alternatives for card manufacturing with minimal environmental impact and lower carbon footprint. The launch of the new SECORA Pay Green solution will let card manufacturers and banks continue issuing innovative, secured cards reducing carbon emissions during the card manufacturing process by double-digit quantities.”

SECORA Pay Green is a plug-and-play solution that can be easily implemented in existing dual-interface card manufacturing facilities, further contributing to fast adoption rates. Another feature of the eCoM module is its ability to seamlessly interact with smartphone antennas. This offers consumers several advantages, in particular high convenience and ease-of-use in tap-to-mobile scenarios. Furthermore, the solution allows a variety of sustainable card materials, like recycled PVC (rPVC), rPETG, PLA, ocean-bound plastic, wood and even paper.

Research shows that customers are increasingly drawn to financial institutions that prioritize sustainable banking practices. In fact, research shows that a significant majority of consumers prefer their bank to provide eco-friendly payment cards. Furthermore, the number of regulations and legal directives relating to environmental protection in the financial industry is increasing. According to forecasts, in 2028 the number of payment cards made of recycled rPVC will grow to around 1.2 billion cards shipped worldwide, nearly a 5-fold increase compared to 2022, when 226 million cards were shipped. (Source: ABI Research, 2023)

* Kilograms of carbon dioxide equivalent (kg CO2e), allowing for a comparison of different products’ climate impacts

**Product Carbon Footprint Report for US for CoM and eCoM, October 2024

Learn more about SECORA™ Pay Green here: www.infineon.com/secorapaygreen

Additional quotes from Infineon Austria can be found under Downloads.

About Infineon Austria

Infineon Technologies Austria AG is a subsidiary of Infineon Technologies AG, a global semiconductor leader in power systems and IoT. Semiconductors are essential for mastering the energy-related challenges of our time and helping to shape the digital transformation. Infineon's microelectronics drive decarbonization and digitalization and enable groundbreaking solutions for green and efficient energy, clean and safe mobility as well as a smart and secure IoT.

Infineon Austria pools competencies for research and development, production as well as global business responsibility. The head office is in Villach, with further branches in Graz, Klagenfurt, Linz, Innsbruck and Vienna. With 5,886 employees (including around 2,500 in research and development) from 79 nations, the company generated revenue of EUR 5.6 billion in the 2023 fiscal year (ending 30 September). With research expenditure of 672 million euros, Infineon Austria is the strongest research company in Austria.

Press Photos

-

Stefan Rohringer, Head of the Infineon Research and Development Centres in Austria: "Graz has been Infineon's global competence centre for contactless technologies since 1998. Our dedicated team has now succeeded in developing the world's first contactless payment card technology that produces up to 100% less plastic waste and enables CO2 savings of more than 60 per cent in the procurement of raw materials and logistics: an important step towards greater sustainability and the economical use of resources in the global payment system."Stefan-Rohringer_Infineon-Austria

Stefan Rohringer, Head of the Infineon Research and Development Centres in Austria: "Graz has been Infineon's global competence centre for contactless technologies since 1998. Our dedicated team has now succeeded in developing the world's first contactless payment card technology that produces up to 100% less plastic waste and enables CO2 savings of more than 60 per cent in the procurement of raw materials and logistics: an important step towards greater sustainability and the economical use of resources in the global payment system."Stefan-Rohringer_Infineon-AustriaJPG | 818 kb | 945 x 1417 px

-

Benno Flecker, Patrick Friesser and Szabolcs Tompa-Antal from the development centre in Graz with SECORA™ Pay Green cards made of wood, paper and ceramic. Benno Flecker: "By integrating the antenna into the security chip of the ATM or credit card for the first time, the card can be completely recycled at the end of its life cycle - the chip module can be broken out of the card and disposed of separately as electronic waste. Alternative materials for the card body are also possible, e.g. ATM or credit cards made of wood, paper, ceramics or even recycled plastic."Pay Green Team in Graz

Benno Flecker, Patrick Friesser and Szabolcs Tompa-Antal from the development centre in Graz with SECORA™ Pay Green cards made of wood, paper and ceramic. Benno Flecker: "By integrating the antenna into the security chip of the ATM or credit card for the first time, the card can be completely recycled at the end of its life cycle - the chip module can be broken out of the card and disposed of separately as electronic waste. Alternative materials for the card body are also possible, e.g. ATM or credit cards made of wood, paper, ceramics or even recycled plastic."Pay Green Team in GrazJPG | 7.41 mb | 5328 x 3552 px

-

With conventional payment cards (left in the picture), a separate foil layer with a copper wire antenna is embedded in the material of the card. The different layers and the copper wire antenna, which covers the entire card body, make simple recycling of conventional contactless payment cards almost impossible. SECORA Pay Green from Infineon is now setting a new standard for the recycling process of dual-interface payment cards. The new eco-friendly Coil-on-Module (eCoM) package combines the security controller and software components as well as the antenna required for contactless transactions.GreenPay_4

With conventional payment cards (left in the picture), a separate foil layer with a copper wire antenna is embedded in the material of the card. The different layers and the copper wire antenna, which covers the entire card body, make simple recycling of conventional contactless payment cards almost impossible. SECORA Pay Green from Infineon is now setting a new standard for the recycling process of dual-interface payment cards. The new eco-friendly Coil-on-Module (eCoM) package combines the security controller and software components as well as the antenna required for contactless transactions.GreenPay_4JPG | 6.43 mb | 5328 x 4000 px

-

At the end of the card's service life, the eCoM package can be broken out of the card and disposed of separately as electronic waste. The unmixed card body can then be recycled as plastic, wood or paper, depending on the material.GreenPay_5

At the end of the card's service life, the eCoM package can be broken out of the card and disposed of separately as electronic waste. The unmixed card body can then be recycled as plastic, wood or paper, depending on the material.GreenPay_5JPG | 7.1 mb | 5328 x 4000 px

-

Leaf-card Secora Pay Green

Leaf-card Secora Pay GreenJPG | 534 kb | 1417 x 2126 px

-

SECORA-Pay-Green-old-and-new

SECORA-Pay-Green-old-and-newJPG | 279 kb | 2126 x 1196 px